Alumina Refractory Castable dị elu

Ozi ngwaahịa

| Aha ngwaahịa | Castable refractory |

| Otu | Simenti dị ala / nnukwu ihe nkedo nke siri ike /Igwe ọkụ alumina dị elu / dị fechaa |

| Ihe mejupụtara | Mkpokọta refractory, powders na binders |

| Atụmatụ | 1.Easy ewu, 2.Good Slag Nguzogide, 3.Good corrosion Resistance, 4.Good Fire Resistance, 5.Energy Saving and Environmental Protection. |

| Ngwa | Ejiri ya nke ọma n'ọkụ ụlọ ọrụ dị elu dị elu. |

| Ngwaahịa | Cement Castable dị ala | Castable ike dị elu |

| Nkọwa | Ihe nkedo simenti dị ala na-ezo aka na nkedo ọhụrụ nwere obere ihe nkedo ciment.Ọdịnaya simenti nke ihe nkedo refractory na-abụkarị 15% ruo 20%, ọdịnaya simenti nke ihe nkedo simenti dị ala bụ ihe dịka 5%, ụfọdụ na-ebelatakwa ruo 1% ruo 2%. | Nkedo ike dị elu nke na-eguzogide ike bụ mkpokọta ike dị elu, ihe mgbakwunye ịnweta, mkpokọta ike dị elu yana ihe mgbochi mgbawa na onye na-eguzogide iyi. |

| Atụmatụ | A na-emeziwanye nkwụsi ike ujo, nguzogide slag, na nguzogide mbuze, karịa brik ndị na-emegharị ahụ. | Ike dị elu, nkwụsi ike dị elu, nkwụsị mmetụta, nkwụsị nke mbuze, mgbochi mmanu mmanu, njikwa ọdịdị aka ike, iguzosi ike n'ezi ihe siri ike, ihe owuwu dị mfe, ịrụ ọrụ nke ọma na ogologo ọrụ. |

| Ngwa | 1.Lining nke dị iche iche okpomọkụ ọgwụgwọ ọkụ, ọkụ ọkụ, aro kilns, rotary kilns, ọkụ ọkụ ọkụ cover, gbawara ọkụ tapholes; 2.Self-flowing low-ciment castables na-adabara elu-okpomọkụ ịgba egbe linings maka ịgba metallurgy na petrochemical catalytic cracking reactors Yiri na-eguzogide ọgwụ, mpụta lining nke kpo oku oku ọkụ mmiri-mma ọkpọkọ, wdg. | Ngwunye oyi akwa na-eguzogide sluice slag,Obere mmiri, coal spout, hopper na silo na metallurgy, coal, thermal ike, chemical,simenti na ụlọ ọrụ ndị ọzọ, na ọkụ ọkụ na-agwakọta silo, sintering silo, feeder, pelletizer, wdg. |

| Ngwaahịa | Alumina Castable dị elu | Castable dị fechaa |

| Nkọwa | Ihe nkedo nke alumina dị elu na-atụgharịcastables mere nke elu-alumina akụrụngwadị ka aggregates na powders, na gbakwunyerena ihe nkedo. | Ihe nkedo dị fechaa nke nwere obere njupụta dị ala bụ nke ciment aluminate, ezigbo ihe alumina dị elu, ceramsite na mgbakwunye. |

| Atụmatụ | Nwere nnukwu n'ibu ike na ezigbo thermal ujo eguzogide, abrasion eguzogide na ndị ọzọ Njirimara. | Obere obere njupụta, obere conductivity thermal, mmetụta mkpuchi ọkụ dị mma, ike mkpakọ dị elu, acid na acid gas na-eguzogide corrosion, mkpuchi okpomọkụ, mkpuchi ọkụ, na obere mmiri absorption. |

| Ngwa | A na-ejikarị ya dị ka mkpuchi dị n'ime nke ọkụ ọkụ, ọkụ ọkụ ọkụ ọkụ ọkụ, ọkụ ọkụ, ite seramiiki na kiln ndị ọzọ. | Enwere ike iji ihe nkedo dị fechaa maka oyi akwa mkpuchi ọkụ nke ọkụ ụlọ ọrụ na-ekpo ọkụ na akụrụngwa a na-ejikwa maka mkpuchi nke ọkpọkọ gas dị elu dị iche iche. |

Ndekọ ngwaahịa

Igwe ọkụ na-ekpo ọkụ

Ọwara Kiln

Rotary Kiln

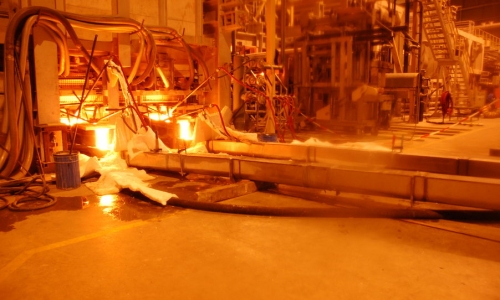

Ụlọ ọrụ ígwè na ígwè: a na-ejikarị eme ihe maka nhazi na ịkwanye ọkụ ọkụ eletrik, igwe na-eme ígwè, ladles na ngwa ndị ọzọ.

Ụlọ ọrụ igwe anaghị agba nchara: ejiri ya maka ịkwachie na ịrụzi ọla kọpa, aluminom, zinc, nickel na igwe ọkụ ndị ọzọ anaghị agbaze na ndị ntụgharị.

Ụlọ ọrụ iko: a na-eji arụ ọrụ na-arụ ọrụ nke igwe iko, ọkụ ọkụ na ngwa ndị ọzọ.

| Aha ngwaahịa | Cement Castable dị ala | |||||

| INDEX | RBTZJ-42 | RBTZJ-60 | RBTZJ-65 | RBTZJS-65 | RBTZJ-70 | |

| Oke okpomoku arụ ọrụ | 1300 | 1350 | 1400 | 1400 | 1450 | |

| Njupụta buru ibu (g/cm3)110 ℃ × 24h ≥ | 2.15 | 2.3 | 2.4 | 2.4 | 2.45 | |

| Ike na-ehulata oyi110 ℃ × 24h (MPa) ≥ | 4 | 5 | 6 | 6 | 7 | |

| Ike Crushing oyi (MPa) ≥ | 110 ℃ × 24h | 25 | 30 | 35 | 35 | 40 |

| CT ℃ × 3h | 50 1300 ℃ × 3h | 55 1350 ℃ × 3h | 60 1400 ℃ × 3h | 40 1400 ℃ × 3h | 70 1400 ℃ × 3h | |

| Mgbanwe Linear na-adịgide adịgide@CT℃×3h(%) | -0.5-0.5 1300 ℃ | -0.5-0.5 1350 ℃ | 0 ~ + 0.8 1400 ℃ | 0 ~ + 0.8 1400 ℃ | 0 ~ + 1.0 1400 ℃ | |

| Nguzogide okpomọkụ (Thermal Shock Resistance)1000 ℃ mmiri) ≥ | - | - | - | 20 | - | |

| Al2O3(%) ≥ | 42 | 60 | 65 | 65 | 70 | |

| CaO(%) ≤ | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | |

| Fe2O3(%) ≤ | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Aha ngwaahịa | Castable ike dị elu | |||||

| INDEX | HS-50 | HS-60 | HS-70 | HS-80 | HS-90 | |

| Oke okpomọkụ na-arụ ọrụ (℃) | 1400 | 1500 | 1600 | 1700 | 1800 | |

| 110℃ Nnukwu njupụta (g/cm3) ≥ | 2.15 | 2.30 | 2.40 | 2.50 | 2.90 | |

| Modul nke mgbawa (MPa) ≥ | 110 ℃ × 24h | 6 | 8 | 8 | 8.5 | 10 |

| 1100 ℃ × 3h | 8 | 8.5 | 8.5 | 9 | 9.5 | |

| 1400 ℃ × 3h | 8.5 1300 ℃ × 3h | 9 | 9.5 | 10 | 15 | |

| Ike Crushing oyi (MPa) ≥ | 110 ℃ × 24h | 35 | 40 | 40 | 45 | 60 |

| 1100 ℃ × 3h | 40 | 50 | 45 | 50 | 70 | |

| 1400 ℃ × 3h | 45 1300 ℃ × 3h | 55 | 50 | 55 | 100 | |

| Mgbanwe ahịrị na-adịgide adịgide(%) | 1100 ℃ × 3h | -0.2 | -0.2 | -0.25 | -0.15 | -0.1 |

| 1400 ℃ × 3h | -0,45 1300 ℃ × 3h | -0.4 | -0.3 | -0.3 | -0.1 | |

| Al2O3(%) ≥ | 48 | 48 | 55 | 65 | 75 | 90 |

| CaO(%) ≤ | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| Fe2O3(%) ≤ | 3.5 | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 |

| Aha ngwaahịa | Alumina Castable dị elu | ||||||

| INDEX | Al2O3 (%) ≥ | CaO(%) ≥ | Refractoriness (℃) | CT℃ × 3h PLC ≤1% | 110 ℃ Mgbe akpọchara (MPa) | ||

| CCS | MOR | ||||||

| Clay Bonded | NL-45 | 45 | - | 1700 | 1350 | 8 | 1 |

| NL-60 | 60 | - | 1720 | 1400 | 9 | 1.5 | |

| NL-70 | 70 | - | 1760 | 1450 | 10 | 2 | |

| Cement jikọtara | GL-42 | 42 | - | 1640 | 1350 | 25 | 3.5 |

| GL-50 | 50 | - | 1660 | 1400 | 30 | 4 | |

| GL-60 | 60 | - | 1700 | 1400 | 30 | 4 | |

| GL-70 | 70 | - | 1720 | 1450 | 35 | 5 | |

| GL-85 | 85 | - | 1780 | 1500 | 35 | 5 | |

| Ejikọchara ciment dị ala | DL-60 | 60 | 2.5 | 1740 | 1500 | 30 | 5 |

| DL-80 | 80 | 2.5 | 1780 | 1500 | 40 | 6 | |

| A na-ekekọta Phosphate | LL-45 | 45 | - | 1700 | 1350 | 20 | 3.5 |

| LL-60 | 60 | - | 1740 | 1450 | 25 | 4 | |

| LL-75 | 75 | - | 1780 | 1500 | 30 | 5 | |

| A na-ejikọta sodium silicate | BL-40 | 40 | - | - | 1000 | 20 | - |

| Aha ngwaahịa | Castable dị fechaa | ||||||

| Oke okpomọkụ na-arụ ọrụ | 1100 | 1200 | 1400 | 1500 | 1600 | ||

| 110℃ Nnukwu njupụta (g/cm3) ≥ | 1.15 | 1.25 | 1.35 | 1.40 | 1.50 | ||

| Modul nke mgbawa (MPa) ≥ | 110 ℃ × 24h | 2.5 | 3 | 3.3 | 3.5 | 3.0 | |

| 1100 ℃ × 3h | 2 | 2 | 2.5 | 3.5 | 3.0 | ||

| 1400 ℃ × 3h | - | - | 3 | 10.8 | 8.1 | ||

| Ike Nchicha oyiMPa) ≥ | 110 ℃ × 24h | 8 | 8 | 11 | 12 | 10 | |

| 1100 ℃ × 3h | 4 | 4 | 5 | 11 | 10 | ||

| 1400 ℃ × 3h | - | - | 15 | 22 | 14 | ||

| Mgbanwe ahịrị na-adịgide adịgide(%) | 1100 ℃ × 3h | -0.65 1000 ℃ × 3h | -0.8 | -0.25 | -0.15 | -0.1 | |

| 1400 ℃ × 3h | - | - | -0.8 | -0.55 | -0.45 | ||

| Nrụpụta ọkụ (W/mk) | 350 ℃ | 0.18 | 0.20 | 0.30 | 0.48 | 0.52 | |

| 700 ℃ | 0.25 | 0.25 | 0.45 | 0.61 | 0.64 | ||

| Al2O3(%) ≥ | 33 | 35 | 45 | 55 | 65 | ||

| Fe2O3(%) ≤ | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 | ||

Ngwa

Ngwugwu & Ụlọ nkwakọba ihe