Akwụkwọ ndụ akwụkwọ ndụ Silicon Carbide

Ozi Ngwaahịa

Ájá carbide silicon akwụkwọ ndụ akwụkwọ ndụbụ ihe e ji aka mee nke nwere usoro kemịkalụ nke SiC. A na-ejikarị ájá quartz, petroleum coke (ma ọ bụ coal coke) na sawdust eme ya site na ịgbaze okpomọkụ dị elu n'ime ọkụ na-eguzogide ọgwụ. Ájá silicon carbide akwụkwọ ndụ akwụkwọ ndụ na-acha akwụkwọ ndụ akwụkwọ ndụ.ma nwee ọtụtụ njirimara na ojiji dị mkpa.

Arụmọrụ nhazi

Arụmọrụ dị elu nke igwe egweri:Ọdịdị na ike nke ihe ndị ahụ na-eme ka ọ nwee ezigbo arụmọrụ ngweri, nke nwere ike iwepụ unyi na oyi akwa oxide n'elu ihe eji arụ ọrụ ahụ ngwa ngwa.

Ezigbo ihe onwunwe na-eme ka onwe ya dị nkọ:Nha na ọdịdị nke ihe ndị ahụ hà nhata ma nwee ọnụ agụba, nke na-eme ka o doo anya na ọ na-eme ka ọ dị nkọ nke ọma dị ka ihe e ji egbutu ihe ma na-eme ka ihe e gbutu ghara ịdị mma.

Ezigbo mgbanwe:Enwere ike ịhazi ya nke ọma na ọtụtụ mmiri ọkụ dị iche iche iji melite arụmọrụ na ịdị mma nhazi.

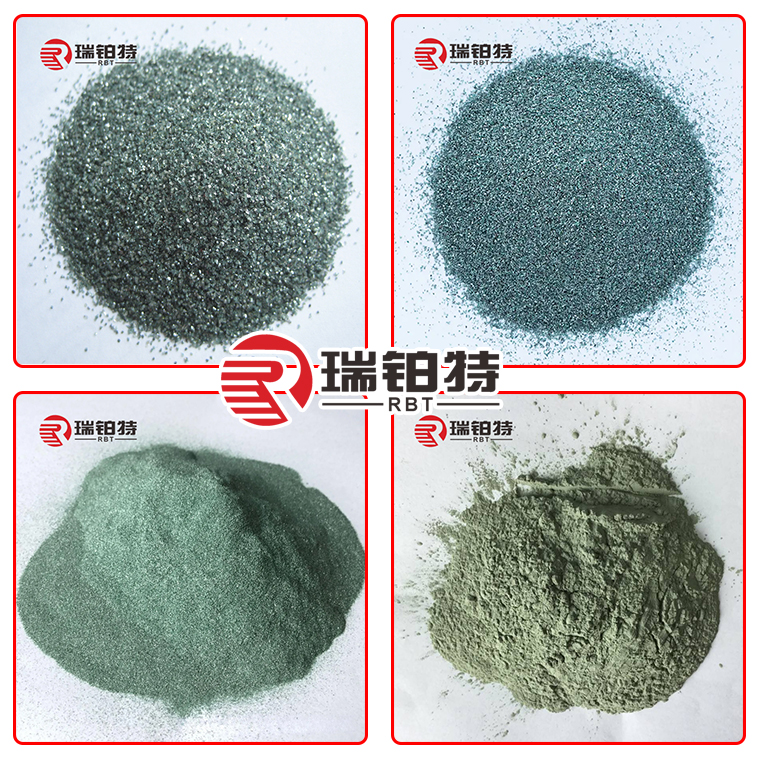

Njirimara anụ ahụ

| Agba | Akwụkwọ ndụ akwụkwọ ndụ |

| Ụdị kristal | Polygon |

| Ike Mohs | 9.2-9.6 |

| Ike Micro | 2840~3320kg/mm² |

| Ebe Mgbaze | 1723 |

| Okpomọkụ Ọrụ Kachasị Elu | 1600 |

| Ezigbo njupụta | 3.21g/cm³ |

| Njupụta buru ibu | 2.30g/cm³ |

Foto Nkọwa

Chaatị Ntụnyere Nha Grit

| Nọmba Grit. | China GB2477-83 | Japan JISR 6001-87 | ANSI nke mba Amerịka (76) | 欧洲磨料 FEPA(84) | ISO(86) |

| 4 | 5600-4750 |

| 5600-4750 | 5600-4750 | 5600-4750 |

| 5 | 4750-4000 |

| 4750-4000 | 4750-4000 | 4750-4000 |

| 6 | 4000-3350 |

| 4000-3350 | 4000-3350 | 4000-3350 |

| 7 | 3350-2800 |

| 3350-2800 | 3350-2800 | 3350-2800 |

| 8 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 | 2800-2360 |

| 10 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 | 2360-2000 |

| 12 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 | 2000-1700 |

| 14 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 | 1700-1400 |

| 16 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 | 1400-1180 |

| 20 | 1180-1000 | 1180-1100 | 1180-1000 | 1180-1000 | 1180-1000 |

| 22 | 1000-850 | - | - | 1000-850 | 1000-850 |

| 24 | 850-710 | 850-710 | 850-710 | 850-710 | 850-710 |

| 30 | 710-600 | 710-600 | 710-600 | 710-600 | 710-600 |

| 36 | 600-500 | 600-500 | 600-500 | 600-500 | 600-500 |

| 40 | 500-425 | - | - | 500-425 | 500-425 |

| 46 | 425-355 | 425-355 | 425-355 | 425-355 | 425-355 |

| 54 | 355-300 | 355-300 | 355-297 | 355-300 | 355-300 |

| 60 | 300-250 | 300-250 | 297-250 | 300-250 | 300-250 |

| 70 | 250-212 | 250-212 | 250-212 | 250-212 | 250-212 |

| 80 | 212-180 | 212-180 | 212-180 | 212-180 | 212-180 |

| 90 | 180-150 | 180-150 | 180-150 | 180-150 | 180-150 |

| 100 | 150-125 | 150-125 | 150-125 | 150-125 | 150-125 |

| 120 | 125-106 | 125-106 | 125-106 | 125-106 | 125-106 |

| 150 | 106-75 | 106-75 | 106-75 | 106-75 | 106-75 |

| 180 | 90-63 | 90-63 | 90-63 | 90-63 | 90-63 |

| 220 | 75-53 | 75-53 | 75-53 | 75-53 | 75-53 |

| 240 | 75-53 | - | 75-53 | - |

Ndepụta Ngwaahịa

| Nha grit | Ihe mejupụtara kemịkalụ% (Site na ibu) | ||

| SiC | F·C | Fe2O3 | |

| 12#-90# | ≥98.50 | ≤0.20 | ≤0.60 |

| 100#-180# | ≥98.00 | ≤0.30 | ≤0.80 |

| 220#-240# | ≥97.00 | ≤0.30 | ≤1.20 |

| W63-W20 | ≥96.00 | ≤0.40 | ≤1.50 |

| W14-W5 | ≥93.00 | ≤0.40 | ≤1.70 |

Ngwa

1. Na-afụ ụfụ:A na-eji ígwè silicon carbide akwụkwọ ndụ akwụkwọ ndụ eme ihe dị ka ihe na-emebi ihe n'ọtụtụ ụlọ ọrụ dị iche iche, gụnyere ụgbọ ala, ụgbọelu, ọrụ ígwè, na ọla. A na-eji ya gwerie, bee, na ịchacha ọla siri ike na seramiiki.

2. Ihe na-anaghị emegharị ahụ:A na-ejikwa ígwè silicone dị ndụ eme ihe dị ka ihe na-anaghị emegharị ahụ n'oge okpomọkụ dị elu dịka ọkụ na ọkụ n'ihi oke okpomọkụ ya na obere mmụba okpomọkụ.

3. Ngwaọrụ Eletrọniki:A na-eji ígwè silicon carbide akwụkwọ ndụ akwụkwọ ndụ eme ihe dị ka ihe e ji eme ihe maka ngwaọrụ eletrọniki dịka LED, ngwaọrụ ike, na ngwaọrụ microwave n'ihi ike eletrik ya dị mma na nkwụsi ike okpomọkụ.

4. Ike anyanwụ:A na-eji ígwè silicon carbide akwụkwọ ndụ akwụkwọ ndụ eme ihe dị ka ihe eji emepụta panel anyanwụ n'ihi oke okpomọkụ ya na obere mmụba okpomọkụ, nke na-enyere aka iwepụ okpomọkụ a na-enweta n'oge ọrụ panel anyanwụ.

5. Ịrụ ọrụ ígwè:A na-eji silicon carbide akwụkwọ ndụ akwụkwọ ndụ eme ihe dị ka ihe na-eme ka ọ ghara ịdị ọcha n'imepụta ígwè na ígwè. Ọ na-enyere aka iwepụ ihe ndị na-adịghị mma n'ime ígwè a gbazere agbaze ma melite mma nke ngwaahịa ikpeazụ.

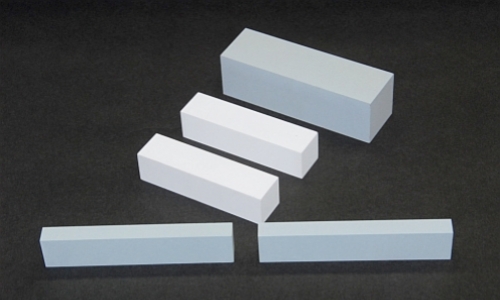

6. Seramiki:A na-eji ígwè silicon carbide akwụkwọ ndụ akwụkwọ ndụ eme ihe dị ka ihe eji emepụta seramiiki dị elu dịka ngwaọrụ ịcha ihe, akụkụ ndị na-eguzogide iyi, na ihe ndị na-ekpo ọkụ dị elu n'ihi ike ya dị elu, ike dị elu, na nkwụsi ike okpomọkụ dị mma.

Ngwugwu na Ụlọ nkwakọba ihe

| Ngwugwu | Akpa 25KG | Akpa 1000KG |

| Ọnụọgụ | Tọn 24-25 | Tọn iri abụọ na anọ |

Nkọwapụta Ụlọ ọrụ

Shandong Robert New Material Co., Ltd.dị na Zibo City, Shandong Province, China, nke bụ ebe mmepụta ihe na-adịghị agbanwe agbanwe. Anyị bụ ụlọ ọrụ ọgbara ọhụrụ nke na-ejikọta nyocha na mmepe, mmepụta, ire ere, imewe na owuwu nke ọkụ, teknụzụ, na ihe ndị na-adịghị agbanwe agbanwe mbupụ. Anyị nwere akụrụngwa zuru oke, teknụzụ dị elu, ike teknụzụ siri ike, ịdị mma ngwaahịa dị mma, na aha ọma. Ụlọ ọrụ mmepụta anyị na-ekpuchi ihe karịrị eka 200 na mmepụta kwa afọ nke ihe ndị na-adịghị agbanwe agbanwe dị ihe dị ka tọn 30000 na ihe ndị na-adịghị agbanwe agbanwe na-adịghị agbanwe agbanwe bụ tọn 12000.

Isi ngwaahịa anyị nke ihe ndị na-adịghị mma gụnyere:ihe ndị na-anaghị agbanwe agbanwe nke alkaline; ihe ndị na-anaghị agbanwe agbanwe nke silicon aluminom; ihe ndị na-anaghị agbanwe agbanwe nke na-enweghị ọdịdị; ihe ndị na-anaghị agbanwe agbanwe nke na-eme ka ihe ghara ịdị ọcha; ihe ndị na-anaghị agbanwe agbanwe pụrụ iche; ihe ndị na-anaghị agbanwe agbanwe nke na-arụ ọrụ maka sistemụ ndị na-aga n'ihu.

Ajụjụ Ndị A Na-ajụkarị

Ị chọrọ enyemaka? Jide n'aka na ị gara na ebe nkwado anyị maka azịza nye ajụjụ gị!

Anyị bụ ezigbo ndị nrụpụta ihe, ụlọ ọrụ mmepụta ihe anyị bụ ọkachamara n'ịmepụta ihe ndị na-anaghị emegharị ahụ ruo ihe karịrị afọ iri atọ. Anyị na-ekwe nkwa inye ọnụahịa kacha mma, ọrụ kacha mma tupu ere na mgbe erechara ya.

Maka usoro mmepụta ọ bụla, RBT nwere usoro QC zuru oke maka ihe mejupụtara kemịkalụ na ihe ndị dị na ya. Anyị ga-anwale ngwaahịa ndị ahụ, a ga-ebugakwa asambodo ịdị mma ya na ngwaahịa ndị ahụ. Ọ bụrụ na ị nwere ihe pụrụ iche achọrọ, anyị ga-agbalị ike anyị niile ịnabata ha.

Dabere na ọnụọgụgụ, oge nnyefe anyị dị iche. Mana anyị na-ekwe nkwa izipu ya ozugbo enwere ike yana ịdị mma a na-ekwe nkwa.

N'ezie, anyị na-enye ihe nlele n'efu.

Ee, n'ezie, a na-anabata gị ịga leta ụlọ ọrụ RBT na ngwaahịa anyị.

Enweghị oke, anyị nwere ike inye ndụmọdụ na ngwọta kacha mma dịka ọnọdụ gị si dị.

Anyị anọwo na-emepụta ihe ndị na-anaghị emegharị ahụ ihe karịrị afọ iri atọ, anyị nwere nkwado teknụzụ siri ike na ahụmịhe bara ụba, anyị nwere ike inyere ndị ahịa aka ịmepụta ebe dị iche iche ma nye ọrụ otu nkwụsị.