Dịka ọmụmaatụ, ihe atọ dị mkpa maka imepụta iko gụnyere oven agbaze iko n'elu mmiri, oven tin float na oven annealing iko. N'ime usoro mmepụta iko, oven agbaze iko bụ ọrụ maka ịgbaze ihe ndị e ji iko mee ka ha bụrụ mmiri iko ma mee ka ha doo anya, mee ka ha dị ka otu ma jụọ oyi ruo okpomọkụ achọrọ maka ịkpụzi. Oven tin bụ ihe dị mkpa maka ịkpụzi iko. Mmiri iko nwere okpomọkụ nke 1050 ~ 1100℃ na-esi na ọwa mmiri na-asọba gaa na mmiri tin na oven tin. A na-eme ka mmiri iko ahụ dị larịị ma na-egbuke egbuke n'elu oven tin ahụ, a na-ejikwa ya site na ịdọkpụ igwe, ihe nchekwa n'akụkụ na igwe eserese akụkụ iji mepụta rịbọn iko nke obosara na ọkpụrụkpụ achọrọ. Ọ na-ahapụkwa tin ahụ mgbe ọ na-ajụ oyi nwayọ ruo 600℃ n'oge usoro ịga n'ihu. Ọrụ nke oven annealing bụ iwepụ nrụgide fọdụrụnụ na enweghị nhazi anya nke iko a na-ese n'elu mmiri, na ime ka nhazi ime nke iko ahụ sie ike. Ribọn iko na-aga n'ihu nke nwere okpomọkụ nke ihe dị ka 600℃ nke tin bath kpatara na-abanye n'oven annealing site na tebụl mgbanwe roller. Ngwa ọkụ atọ a niile dị mkpa chọrọ ihe ndị na-anaghị emegharị ahụ. Iji hụ na ọkụ iko na-agbaze na-arụ ọrụ nke ọma ma kwụsie ike, ọ bụ ihe a na-apụghị ikewapụ na nkwado nke ọtụtụ ihe ndị na-anaghị emegharị ahụ. Ndị a bụ ụdị ihe 9 nke ihe ndị na-anaghị emegharị ahụ a na-ejikarị eme ihe n'ime ọkụ iko na njirimara ha:

Brick silica maka oven iko:

Isi ihe mejupụtara ya bụ: silicon dioxide (SiO2), ihe dị n'ime ya kwesịrị ịdị elu karịa 94%. Okpomọkụ ọrụ: okpomọkụ kachasị elu na-arụ ọrụ bụ 1600~1650℃. Atụmatụ ya: ezigbo iguzogide mbuze acidic slag, mana ọ naghị eguzogide mbuze ihe na-efe efe alkaline. A na-ejikarị ya eme ihe maka nnukwu arches, mgbidi ara na obere ọkụ.

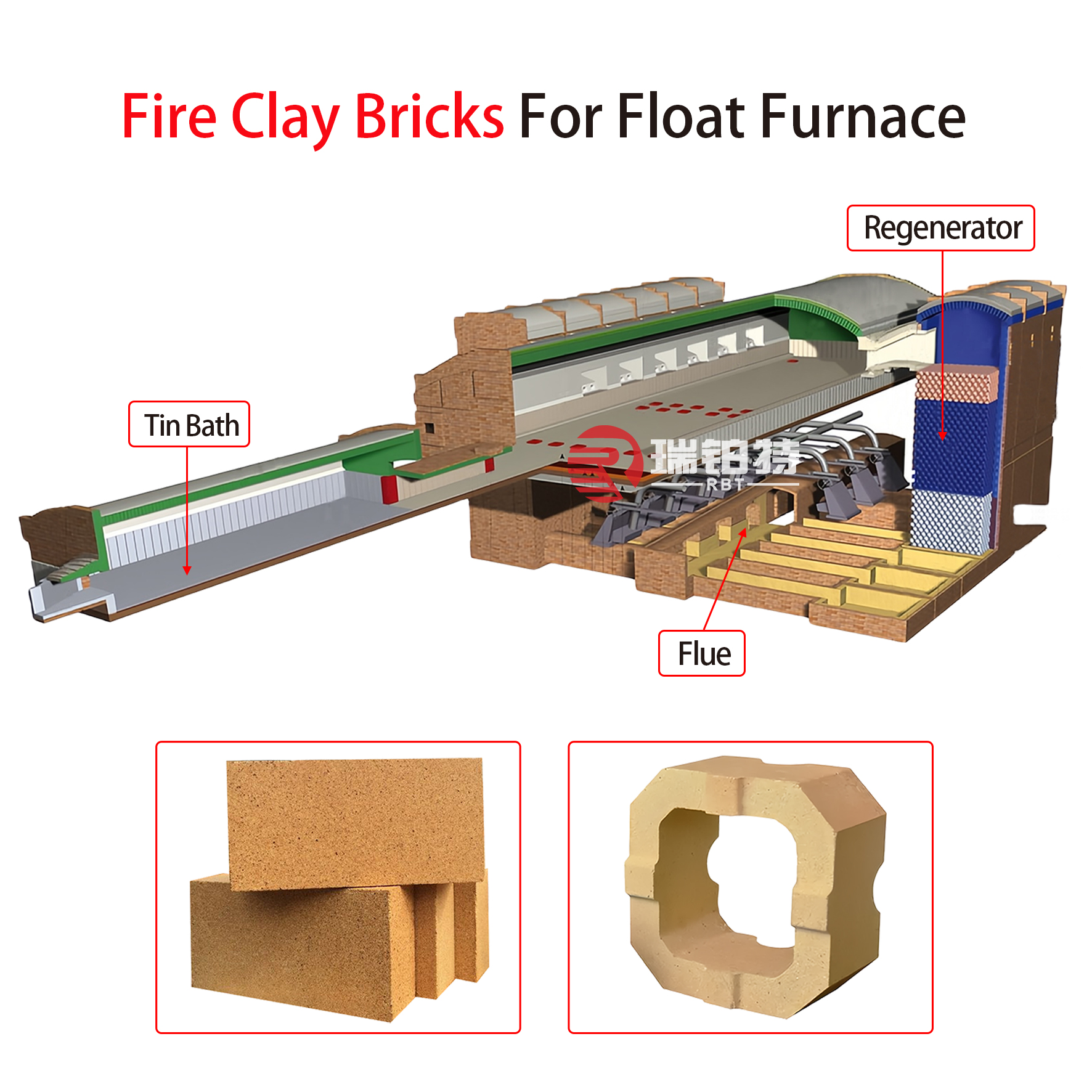

Brọk ụrọ ọkụ maka ọkụ iko:

Ihe ndị bụ isi e ji mee ya: Al2O3 na SiO2, ọdịnaya Al2O3 dị n'etiti 30% ~ 45%, SiO2 dị n'etiti 51% ~ 66%. Okpomọkụ ọrụ: okpomọkụ kachasị elu bụ 1350 ~ 1500℃. Atụmatụ: Ọ bụ ihe na-adịghị ike acidic nke nwere ezigbo refractory, nkwụsi ike okpomọkụ na obere conductivity okpomọkụ. A na-ejikarị ya eme ihe maka ihe owuwu nke ala nke ọdọ mmiri ọkụ, mgbidi ọdọ mmiri nke akụkụ ọrụ na ụzọ, mgbidi, arch, brik checker ala na flue nke ụlọ nchekwa okpomọkụ.

Brọk alumina dị elu maka ọkụ iko:

Isi ihe mejupụtara ya: SiO2 na Al2O3, mana ọdịnaya Al2O3 kwesịrị ịdị karịa 46%. Okpomọkụ ọrụ: Oke okpomọkụ ọrụ kachasị bụ 1500~1650℃. Atụmatụ: Ezigbo nguzogide nchara, ọ nwekwara ike iguzogide nchara sitere na slag acidic na alkaline. A na-ejikarị ya eme ihe n'ime ụlọ nchekwa okpomọkụ, yana ihe ndị na-anaghị emegharị ahụ maka ọdọ mmiri na-arụ ọrụ, ọwa ihe na ihe ndị na-enye nri.

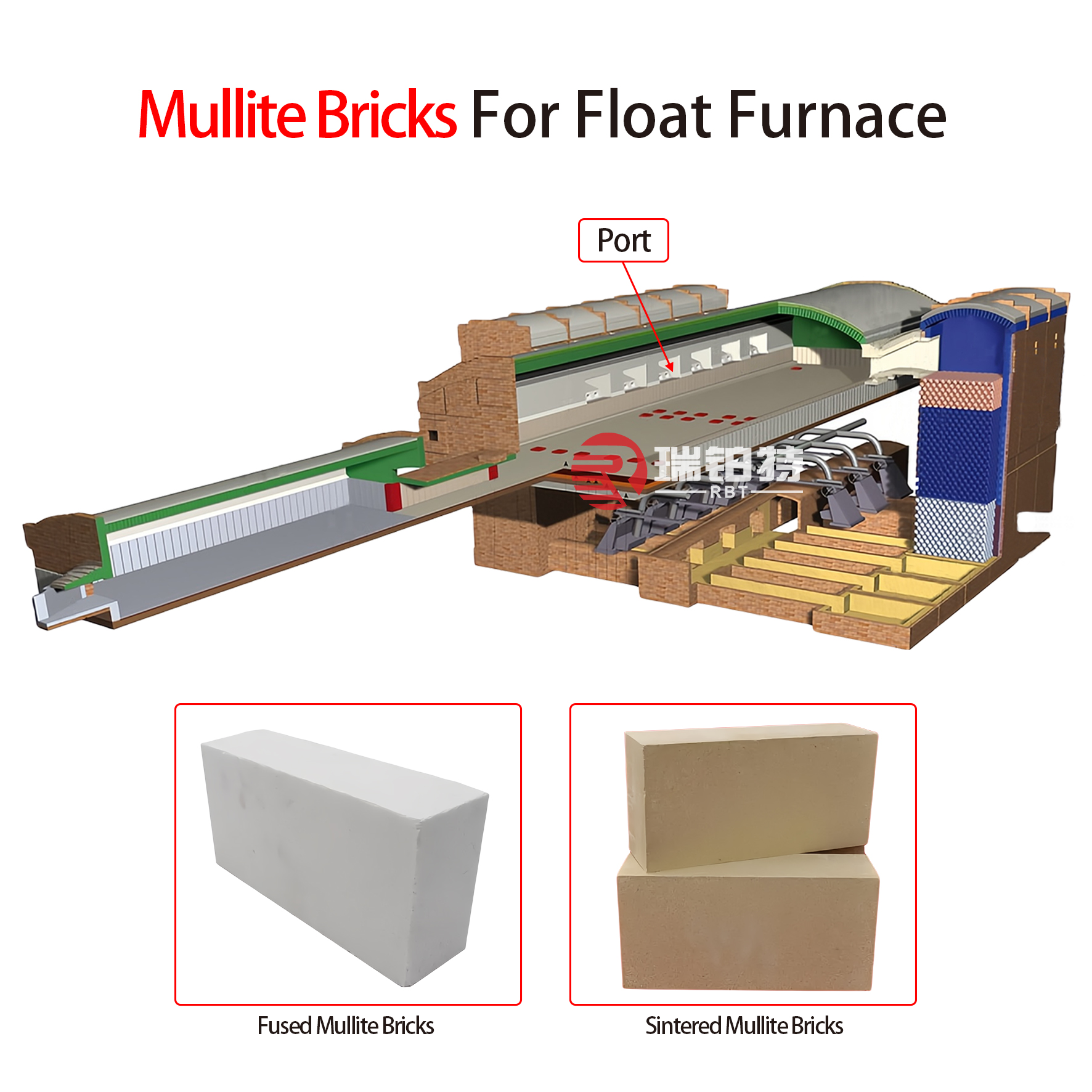

Brọk Mullite:

Isi ihe dị na brik mullite bụ Al2O3, ihe dị na ya dịkwa ihe dịka 75%. N'ihi na ọ bụ kristal mullite, a na-akpọ ya brik mullite. Njupụta ya bụ 2.7-3 2g/cm3, oghere oghere bụ 1%-12%, okpomọkụ kachasị arụ ọrụ bụ 1500~1700℃. A na-ejikarị mullite Sintered eme ihe maka mgbidi ụlọ nchekwa okpomọkụ. A na-ejikarị mullite Fused eme ihe maka mgbidi ọdọ mmiri, oghere nlele, ihe mkpuchi mgbidi, wdg.

Brọk corundum zirconium a gwakọtara agwakọta:

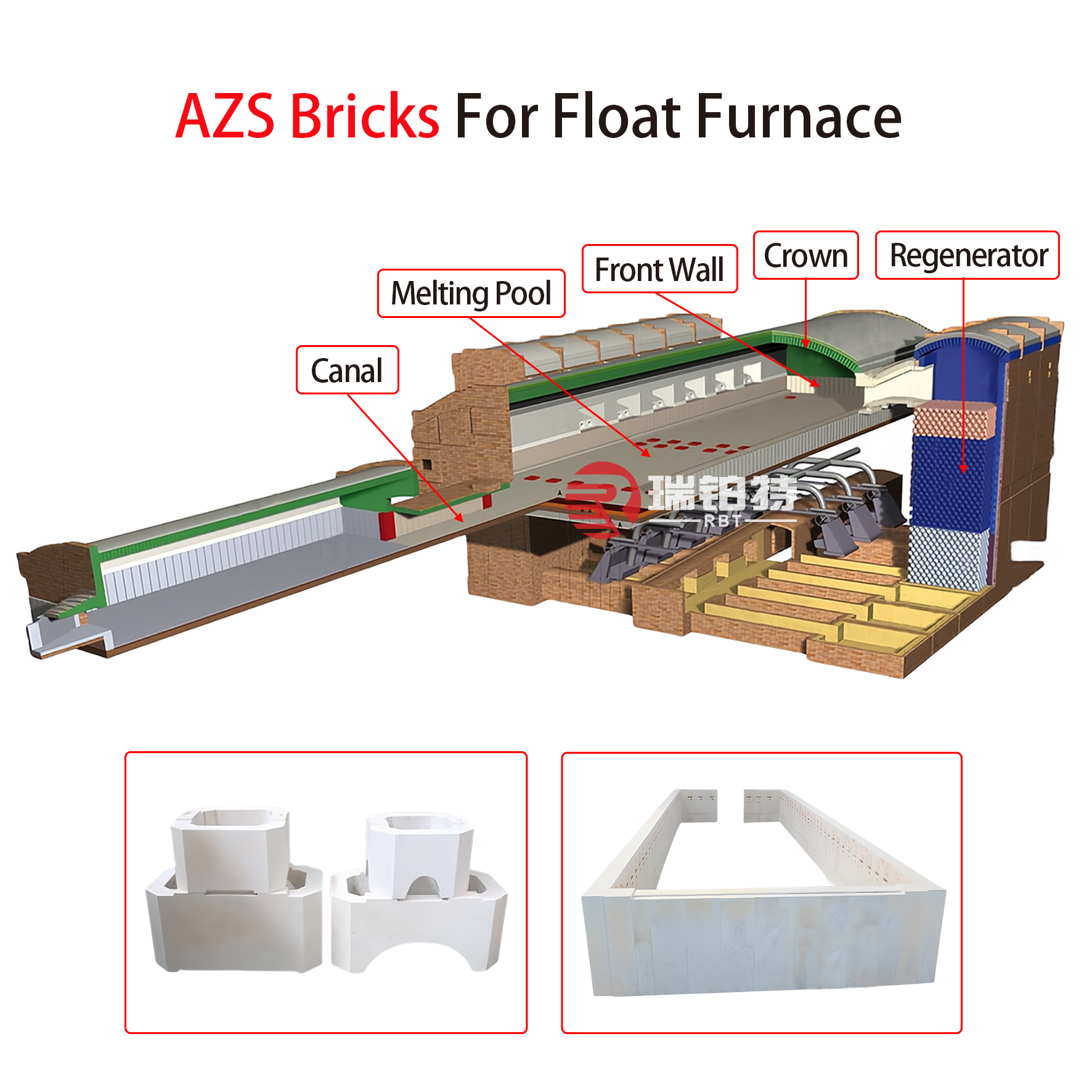

A na-akpọkwa brik zirconium corundum a gwakọtara agwakọta brik ígwè ọcha. N'ozuzu, a na-ekewa brik zirconium corundum a gwakọtara agwakọta n'ọkwa atọ dịka ọdịnaya zirconium si dị: 33%, 36%, na 41%. Brik zirconium corundum ejiri mee ihe n'ụlọ ọrụ iko nwere 50% ~ 70% Al2O3 na 20% ~ 40% ZrO2. Njupụta ya bụ 3.4~ 4.0g/cm3, porosity doro anya bụ 1% ~ 10%, okpomọkụ kachasị arụ ọrụ bụ ihe dị ka 1700℃. A na-eji brik zirconium corundum a gwakọtara agwakọta nwere ọdịnaya zirconium nke 33% na 36% wuo mgbidi ọdọ mmiri ọkụ, mgbidi oghere ara ọkụ, obere oghere ọkụ ọkụ, obere oghere dị larịị nke ọkụ, obere oghere ọkụ ọkụ, obere oghere ọkụ, oghere ire, wdg. A na-eji brik zirconium corundum a gwakọtara agwakọta nke nwere ọdịnaya zirconium nke 41% wuo nkuku mgbidi ọdọ mmiri, oghere mmiri, na akụkụ ndị ọzọ ebe mmiri iko na-emebi ma na-emebi ihe ndị na-adịghị mma nke ukwuu. Ihe a bụ ihe eji eme ka ihe a gwakọtara agwakọta nke a na-ejikarị eme ihe n'ime ụlọ ọrụ iko.

Brọk alumina e jikọta ọnụ:

Ọ na-ezo aka na brik ndị na-adịghị agbanwe agbanwe nke α, β corundum, na brik ndị na-adịghị agbanwe agbanwe nke β corundum, nke mejupụtara ya bụ 92% ~ 94% Al2O3 corundum kristal, njupụta 2.9 ~ 3.05g/cm3, porosity doro anya 1% ~ 10%, na okpomọkụ kachasị elu nke ihe dị ka 1700℃. Alumina a na-ejikọta ọnụ nwere ezigbo iguzogide oghere iko na ihe fọrọ nke nta ka ọ bụrụ mmetọ ọ bụla na mmiri iko. A na-ejikarị ya eme ihe n'akụkụ ọrụ nke ọdọ mmiri, ala ọdọ mmiri, ọwa mmiri, akụkụ ọrụ nke ihe onwunwe nke ọdọ mmiri, ala ọdọ mmiri ihe onwunwe na akụkụ ndị ọzọ nke ọkụ iko na-agbaze nke na-emetụ mmiri iko ahụ ma ghara ịchọ mmetọ na-adịghị agbanwe agbanwe.

Brọk quartz:

Isi ihe mejupụtara ya bụ SiO2, nke nwere ihe karịrị 99%, yana njupụta nke 1.9 ~ 2g/cm3, njupụta nke 1650℃, okpomọkụ ọrụ nke ihe dị ka 1600℃, na iguzogide mbuze acid. A na-eji ya arụ mgbidi ọdọ mmiri nke iko boron acidic, brik oghere thermocouple, wdg.

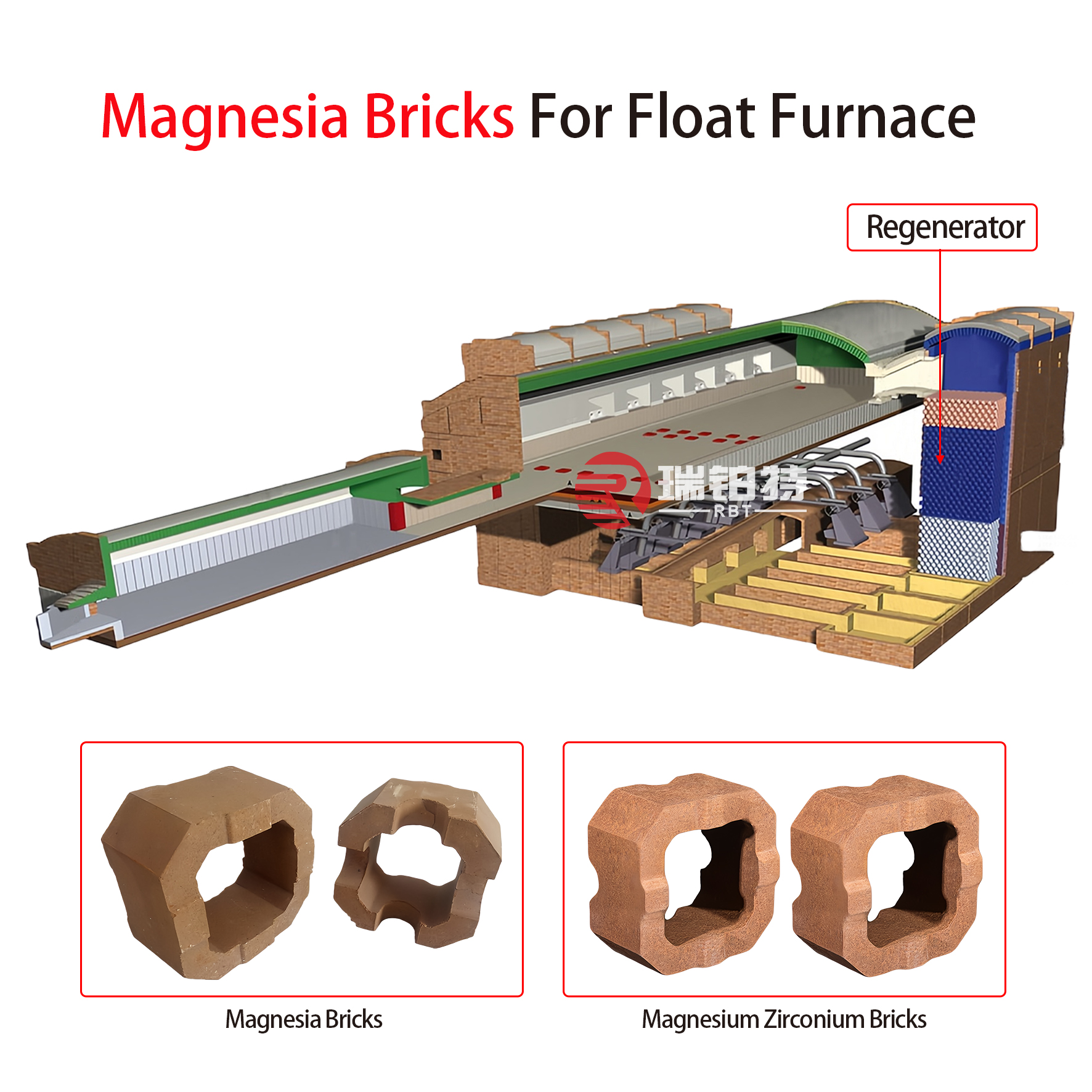

Ihe na-eme ka alkaline ghara ịdị ọcha:

Ihe ndị na-anaghị eguzogide alkaline na-ezo aka na brik magnesia, brik alumina-magnesia, brik magnesia-chrome, na brik forsterite. Arụmọrụ ya bụ iguzogide mmebi nke ihe alkaline, ike ya dịkwa 1900-2000℃. A na-ejikarị ya eme ihe n'elu mgbidi elu nke regenerator nke ọkụ iko na-agbaze, arch regenerator, ahụ grid, na obere nhazi akụkụ ọkụ.

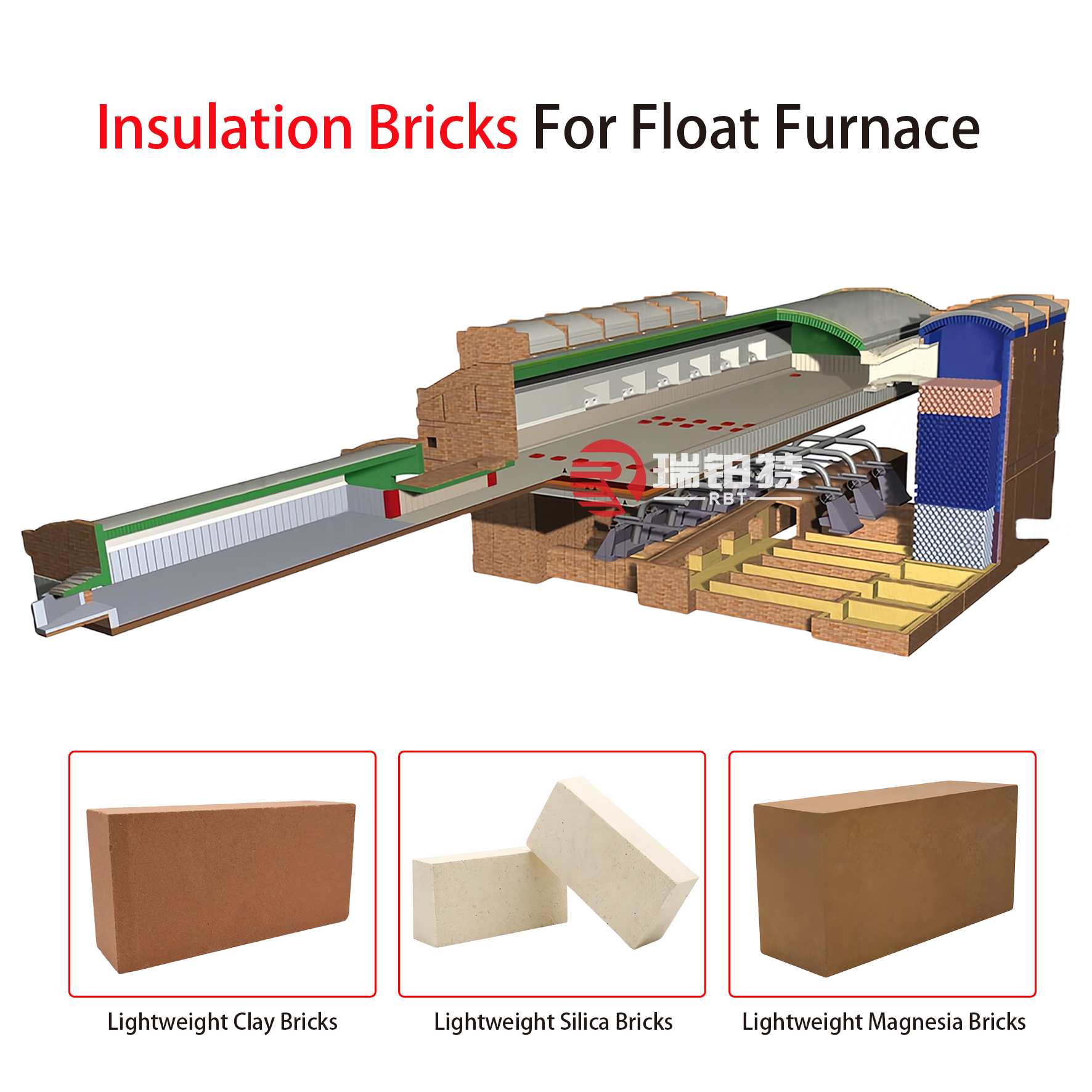

Brọk mkpuchi maka ọkụ iko:

Ebe ọkụ na-agbaze iko buru ibu, arụmọrụ okpomọkụ dịkwa ala. Iji chekwaa ike ma belata oriri, a chọrọ nnukwu ihe mkpuchi maka mkpuchi zuru oke. Karịsịa, a ga-ekpuchi mgbidi ọdọ mmiri, ala ọdọ mmiri, arch, na mgbidi dị na regenerator, akụkụ agbaze, akụkụ ọrụ, wdg. iji belata mgbasa okpomọkụ. Porosity nke brik mkpuchi buru ibu nke ukwuu, ibu ya dị oke mfe, njupụta ya anaghịkwa agafe 1.3g/cm3. Ebe ọ bụ na arụmọrụ mbufe okpomọkụ nke ikuku adịghị mma nke ukwuu, brik mkpuchi nwere nnukwu porosity nwere mmetụta mkpuchi. Coefficient okpomọkụ conductivity ya dị obere karịa nke ihe ndị na-adịghị emegharị ahụ n'ozuzu, yabụ ka porosity buru ibu, otú ahụ ka mmetụta mkpuchi ka mma. E nwere ọtụtụ ụdị brik mkpuchi dị iche iche, gụnyere brik mkpuchi ụrọ, brik mkpuchi silica, brik mkpuchi alumina dị elu na ndị ọzọ.

Oge ozi: Eprel-25-2025