Uru nke brik carbon magnesium bụ:iguzogide mbuze na ezigbo iguzogide ujo okpomọkụ. N'oge gara aga, nsogbu nke brik MgO-Cr2O3 na brik dolomite bụ na ha na-amịkọrọ ihe ndị dị na slag, na-ebute mmụba nhazi, na-ebute mmebi tupu oge eruo. Site na itinye graphite, brik carbon magnesia wepụrụ ihe a na-adịghị mma. Ihe e ji mara ya bụ na slag ahụ na-abanye naanị n'elu ọrụ, yabụ oyi akwa mmeghachi omume E tinyere ya n'elu ọrụ, ihe owuwu ahụ anaghị enwe obere mkpụcha ma na-adịgide ogologo oge.

Ugbu a, na mgbakwunye na brik carbon asphalt ọdịnala na resin nke nwere njikọ magnesia (gụnyere brik magnesia nke a na-etinye mmanụ ọkụ),Brọk carbon nke magnesia a na-ere n'ahịa gụnyere:

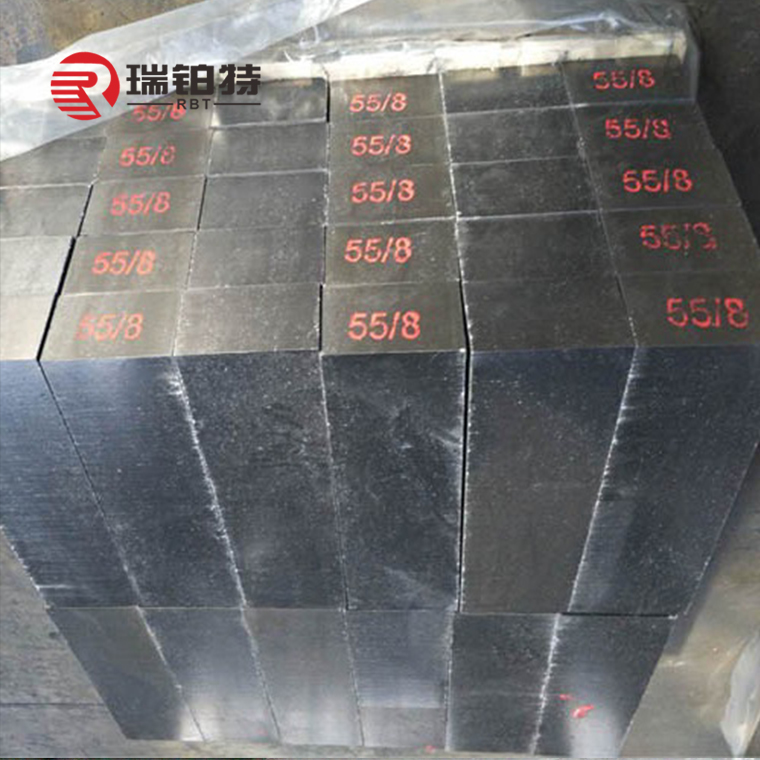

(1) Brọk kabọn Magnesia nke e ji magnesia mee nke nwere 96% ~97% MgO na graphite 94% ~95%C;

(2) Brọk carbon Magnesia nke e ji magnesia mee nke nwere 97.5% ~ 98.5% MgO na graphite 96% ~ 97% C;

(3) Brọk kabọn Magnesia nke e ji magnesia mee nwere 98.5% ~99% MgO na graphite 98% ~C.

Dịka ọnụọgụ carbon si dị, a na-ekewa brik carbon magnesium n'ime:

(I) Brọk magnesia e tinyere mmanụ (ọkwa carbon na-erughị 2%);

(2) Brọk magnesia nke e ji carbon jikọta (ọkwa carbon na-erughị 7%);

(3) Bọkị carbon nke e ji ígwè rụọ (resin sịntetik jikọtara ya na magnesia) (ọdịnaya carbon dị site na 8% ruo 20%, ruo 25% n'ọnọdụ ole na ole). A na-agbakwụnyekarị ihe ndị na-egbochi antioxidant na brik carbon nke asphalt/resin jikọtara ya na magnesia (ọdịnaya carbon dị site na 8% ruo 20%).

A na-emepụta brik carbon Magnesia site na ijikọta ájá MgO dị ọcha na scaly graphite, carbon black, wdg. Usoro mmepụta ahụ gụnyere usoro ndị a: ịchacha ihe, nyocha, nhazi, ịgwakọta dịka nhazi usoro ihe na arụmọrụ ntọala ngwaahịa si dị, dịka njikọta ahụ si dị. A na-ebuli okpomọkụ nke ụdị ihe nnọchi anya ahụ ruo ihe dị ka 100 ~ 200℃, a na-agwakọta ya na ihe njikọ ahụ iji nweta ihe a na-akpọ apịtị MgO-C (ngwakọta ahụ akwụkwọ ndụ akwụkwọ ndụ). A na-akpụ ihe apịtị MgO-C nke ejiri resin sịntetik (karịsịa resin phenolic) n'ọnọdụ oyi; a na-akpụ ihe apịtị MgO-C jikọtara ya na asphalt (a na-ekpo ọkụ ruo ọnọdụ mmiri mmiri) n'ọnọdụ ọkụ (ihe dị ka 100°C). Dịka nha ogbe na ihe achọrọ maka arụmọrụ nke ngwaahịa MgO-C si dị, enwere ike iji ngwa vibration vacuum, ngwa ịkpụzi mkpakọ, extruders, igwe isostatic, igwe ọkụ, ngwa ọkụ, na ngwa ramming iji hazie ihe apịtị MgO-C ka ọ bụrụ ọdịdị zuru oke. A na-etinye ahụ MgO-C e kpụrụ n'ime ọkụ ọkụ na 700~1200°C maka ọgwụgwọ okpomọkụ iji gbanwee ihe na-ejikọ ya ka ọ bụrụ carbon (a na-akpọ usoro a carbonization). Iji mee ka njupụta nke brik carbon magnesia dịkwuo elu ma mee ka njikọ ahụ sie ike, enwere ike iji ihe ndị yiri ihe na-ejikọta ya tinye brik ahụ n'ime ite.

Taa, a na-ejikarị resin sịntetik (karịsịa resin phenolic) eme ihe dị ka ihe na-ejikọ brik carbon magnesia.Ojiji nke brik carbon nke e ji ígwè senti mee nke nwere njikọ magnesia nwere uru ndị a:

(1) Akụkụ gburugburu ebe obibi na-enye ohere nhazi na mmepụta nke ngwaahịa ndị a;

(2) Usoro imepụta ngwaahịa n'okpuru ọnọdụ ngwakọta oyi na-azọpụta ike;

(3) Enwere ike ịhazi ngwaahịa a n'okpuru ọnọdụ na-anaghị agwọ ọrịa;

(4) Ma e jiri ya tụnyere ihe e ji ejikọta asphalt, ọ dịghị usoro plastik ọ bụla;

(5) Mmụba nke kabọn (ọtụtụ graphite ma ọ bụ bituminous coal) nwere ike ime ka iguzogide iyi na iguzogide slag dịkwuo mma.

Oge ozi: Febụwarị-23-2024