Ihe mkpuchi silicon Carbide

| NgwaahịaAha | Ihe mkpuchi silicon Carbide | ||

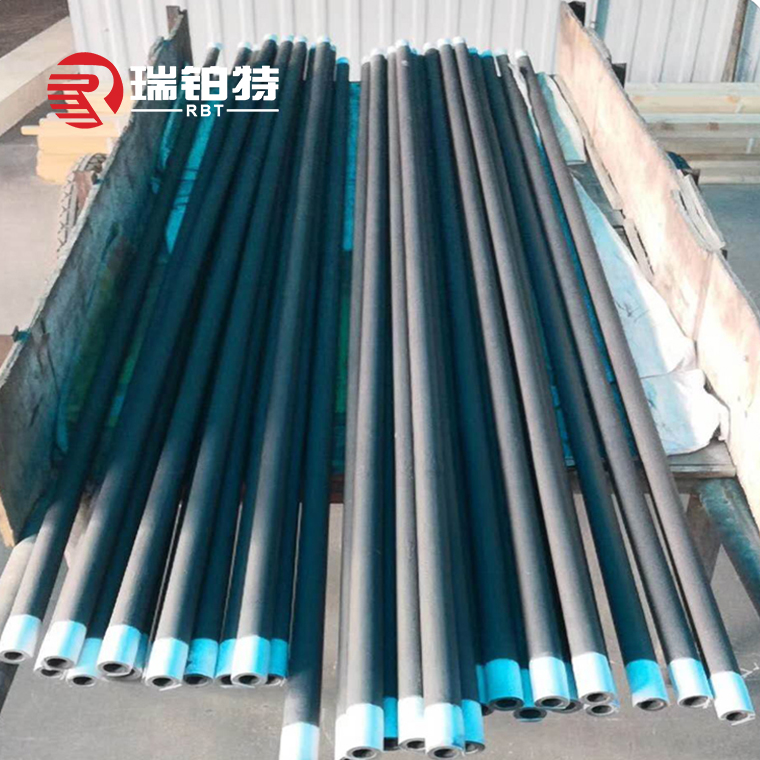

| Nkọwa | 1. Silicon carbide mkpara bụ mkpara ekara na tubular na-abụghị ọla elu okpomọkụ eletriki ọkụ ọkụ mere nke elu-ọcha green hexagonal silicon carbide dị ka isi akụrụngwa, esichara n'ime oghere dị ka ụfọdụ ihe ruru, na sintered na 2200 ° C maka siliconization dị elu, recrystallization na sintering. 2. The nkịtị ojiji okpomọkụ na oxidizing ikuku nwere ike iru 1450 Celsius C, na-aga n'ihu ojiji nwere ike iru 2000 awa. | ||

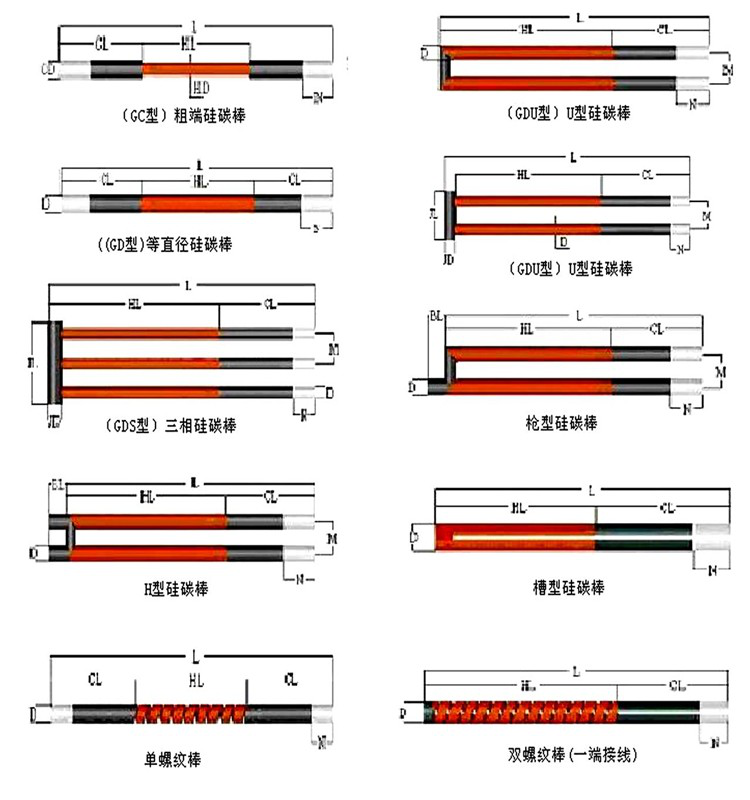

| Nlereanya | GD (mkpanaka nha nha nhata);GC (mkpanaka butt);GDC (mkpanaka yiri U);GDQ (mkpụrụ osisi ụdị egbe);GDH (mkpụrụ osisi ụdị H);Obere mkpanaka;mkpanaka omenala | ||

| Atụmatụ | 1. Nnukwu okpomọkụ na-eguzogide 2. Nguzogide oxidation 3. Nguzogide corrosion 4. Ngwa ngwa kpo oku 5. Ogologo ndu 6. Obere nrụrụ na elu okpomọkụ 7. Nrụnye na mmezi dị mfe | ||

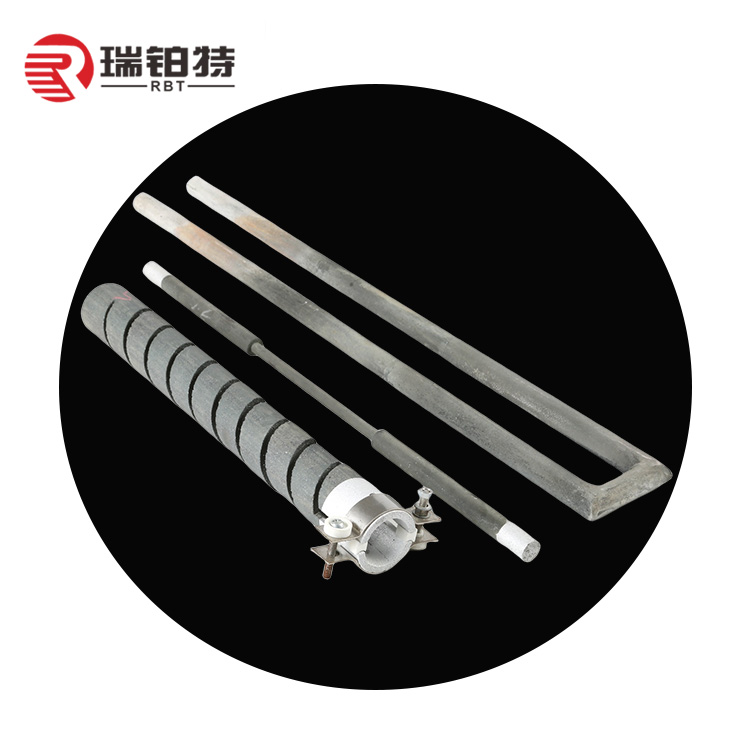

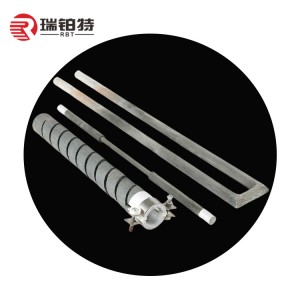

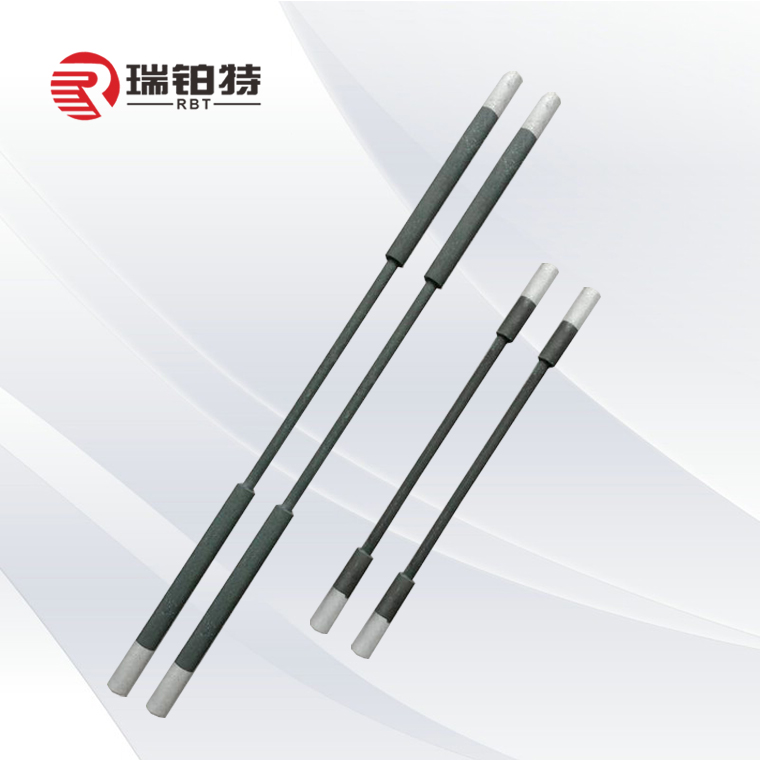

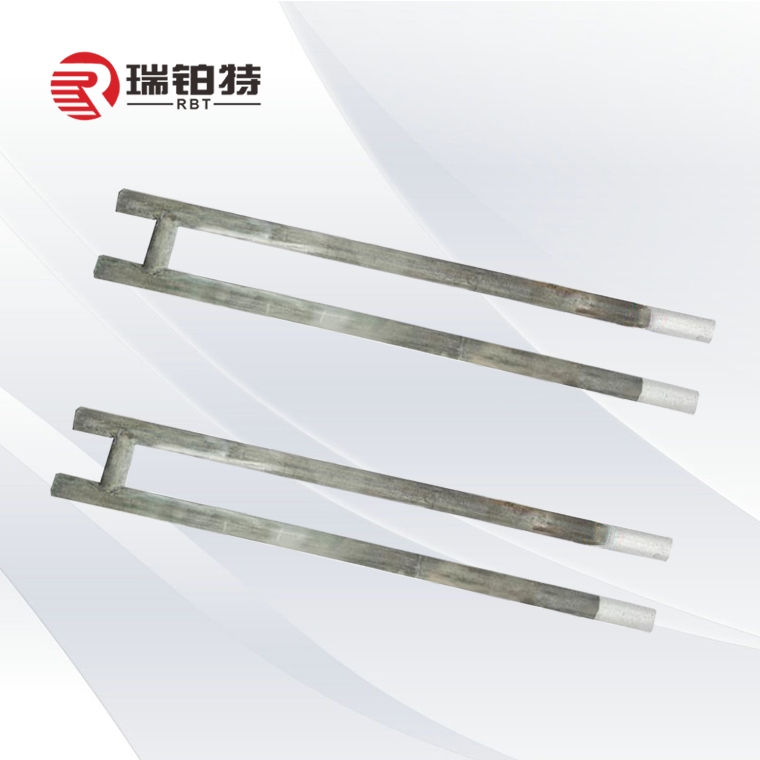

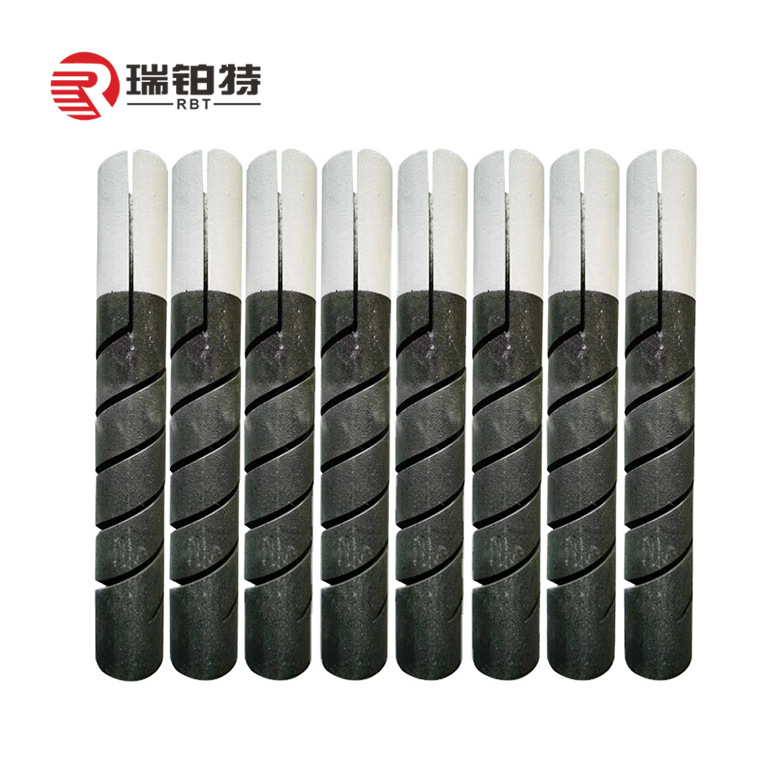

Foto nkọwa

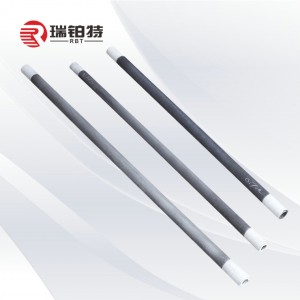

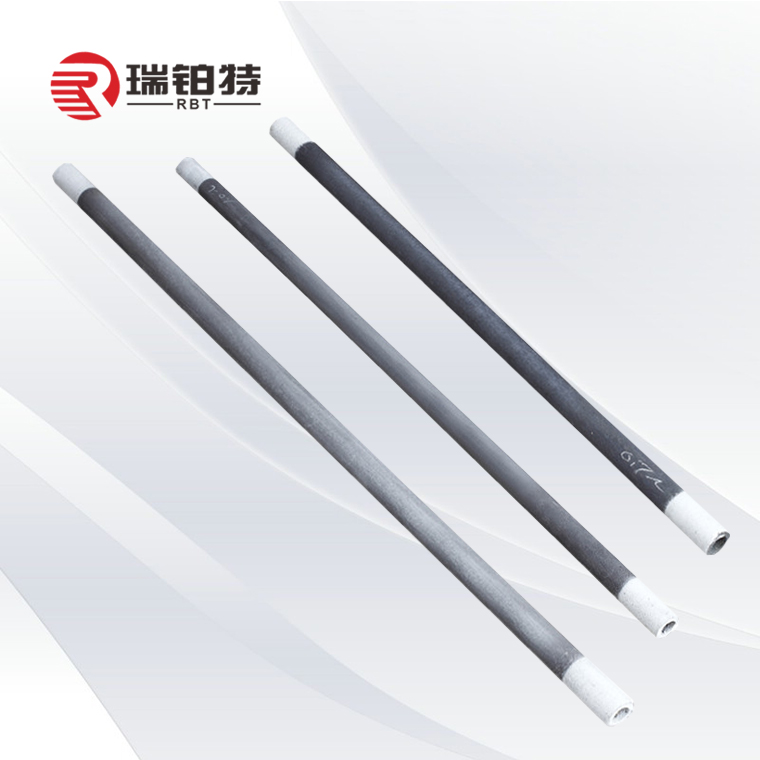

GD (Mkpụrụ osisi Silicon Carbide nha nha nhata)

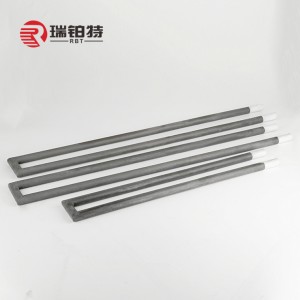

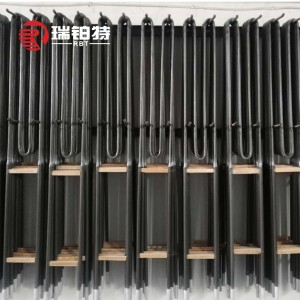

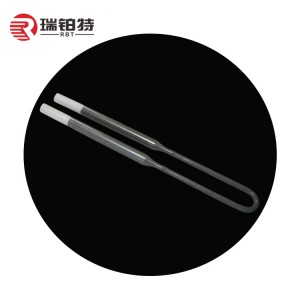

GDC (Mkpụrụ osisi Silicon Carbide nke yiri U)

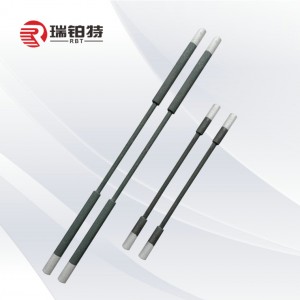

GC (Mkpụrụ osisi Silicon Carbide Dumbbell)

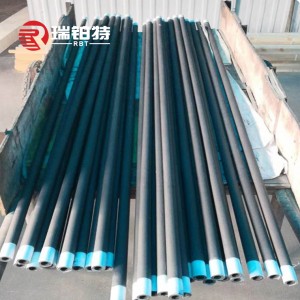

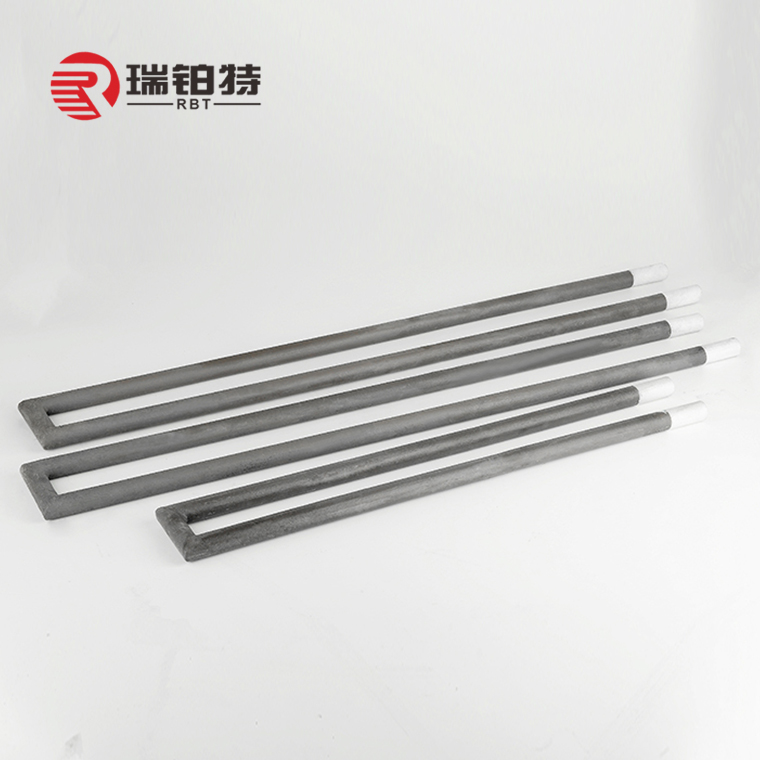

mkpanaka Silicon Carbide akụkụ aka nri

Ngwakọta mkpanaka Silicon Carbide

GDQ (Ụdị égbè Silicon Carbide mkpanaka)

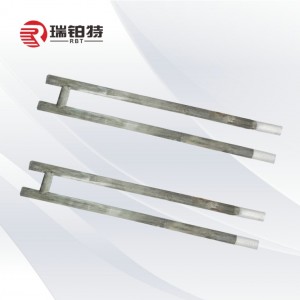

GDH (H-ụdị Silicon Carbide mkpanaka)

Spiral Silicon Carbide mkpanaka

Ọnụ ụzọ ámá Ụdị Silicon Carbide mkpanaka

Ngwakọta mkpanaka Silicon Carbide

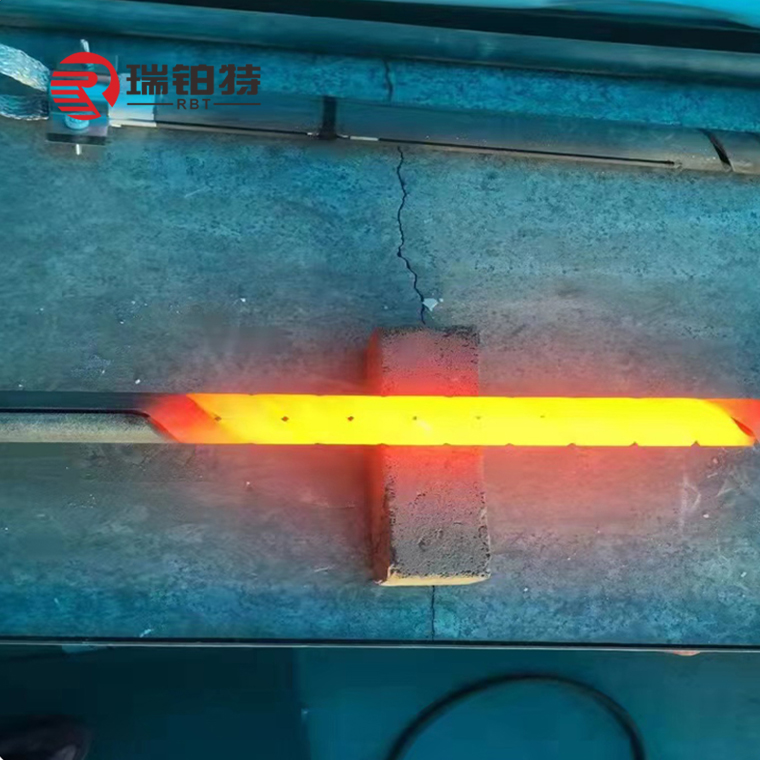

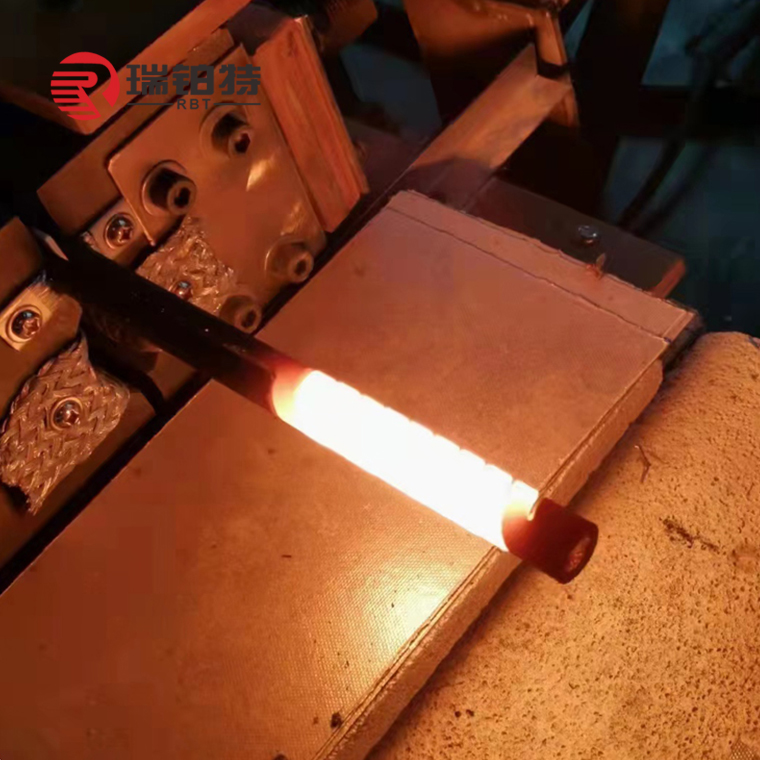

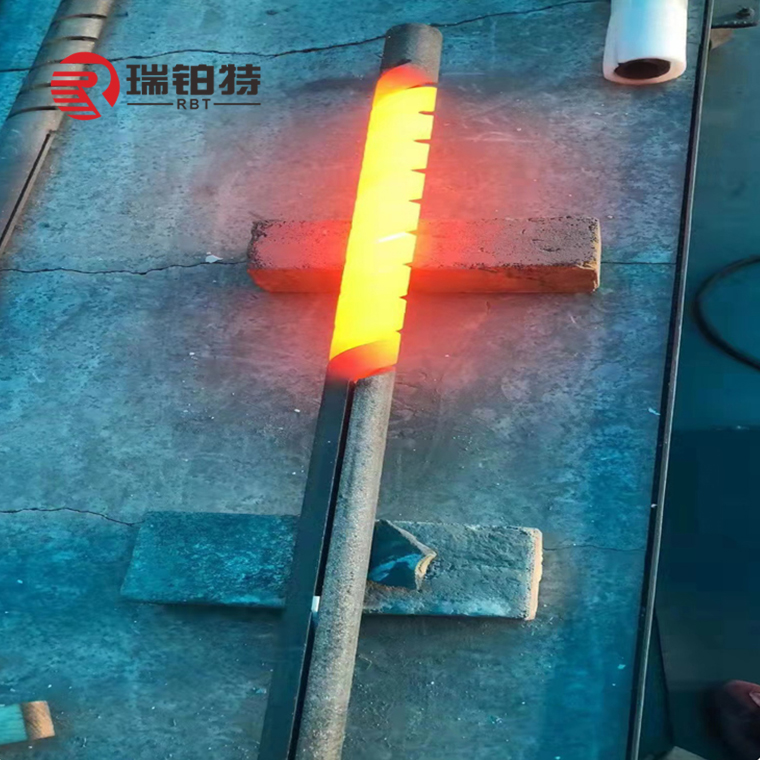

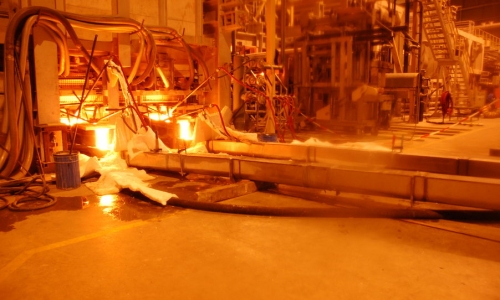

Ngosipụta mmetụta

Ndekọ ngwaahịa

| Ihe | Nkeji | Ụbọchị |

| Ọdịnaya nke SiC | % | 99 |

| Ọdịnaya nke SiO2 | % | 0.5 |

| Ọdịnaya nke Fe2O3 | % | 0.15 |

| Ọdịnaya nke C | % | 0.2 |

| Njupụta | g/cm3 | 2.6 |

| Porosity pụtara | % | <18 |

| Ike na-eguzogide nrụgide | Mpa | ≥120 |

| Na-ehulata Ike | Mpa | ≥80 |

| Okpomọkụ na-arụ ọrụ | ℃ | ≤1600 |

| Ọnụọgụ nke Thermal Mgbasawanye | 10-6/℃ | <4.8 |

| Nrụpụta okpomọkụ | J/Kg ℃ | 1.36*10 |

Ngwa

A na-ejikarị ya na mpaghara okpomọkụ dị elu dị ka ngwá electronic, ihe magnetik, metallurgy powdery, ceramics, glass,

semiconductor, nyocha na nnwale, na nyocha sayensị, wee bụrụ oghere ọwara, igwe rola, iko iko, oghere.

ọkụ ọkụ, ọkụ muffle, ọkụ ọkụ na ọkụ ọkụ eletrik maka akụrụngwa kpo oku.

Igwe ọkụ iko

Roller Kiln

Ọwara Kiln

Igwe ọkụ na-agbaze

Ngwugwu & Ụlọ nkwakọba ihe

Ajụjụ a na-ajụkarị

Achọrọ enyemaka?Jide n'aka na ịga na forums nkwado anyị maka azịza nye ajụjụ gị!

Anyị bụ ezigbo emeputa, ụlọ ọrụ anyị bụ ọkachamara na-emepụta ihe refractory maka ihe karịrị afọ 30.Anyị na-ekwe nkwa ịnye ọnụahịa kacha mma, ọrụ izizi ahịa na mgbe irechara.

Maka usoro mmepụta nke ọ bụla, RBT nwere usoro QC zuru ezu maka ihe mejupụtara kemịkalụ na ihe anụ ahụ.Na anyị ga-anwale ngwongwo ndị ahụ, a ga-ebufekwa akwụkwọ ikike na ngwaahịa.Ọ bụrụ na ị nwere ihe pụrụ iche chọrọ, anyị ga-agbalị ike anyị niile ịnabata ha.

Dabere na ọnụ ọgụgụ, oge nnyefe anyị dị iche.Ma anyị na-ekwe nkwa ibupu ngwa ngwa o kwere omume na mma ekwe nkwa.

N'ezie, anyị na-enye free samples.

Ee, n'ezie, ị na-anabata ileta RBT ụlọ ọrụ na anyị ngwaahịa.

Enweghị oke, anyị nwere ike ịnye ndụmọdụ na ngwọta kachasị mma dịka ọnọdụ gị si dị.

Anyị na-eme ihe refractory ihe karịrị afọ 30, anyị nwere nkwado teknụzụ siri ike na ahụmahụ bara ụba, anyị nwere ike inyere ndị ahịa aka ịmepụta kilns dị iche iche ma nye otu nkwụsị ọrụ.