Silicon Carbide Cantilever Paddles

Ụdị ngwaahịa

1. Mmeghachi omume sintered silicon carbide ngwaahịa(RBSiC Ngwaahịa)

Reaction bonded silicon carbide (RBSiC) bụ ihe seramiiki injinịa dị elu nke na-ewepụta usoro njikọ nke silicon carbide site na ịmeghachi carbon na silicon mmiri mmiri n'efu n'okpuru ọnọdụ okpomọkụ dị elu. Ihe mejupụtara ya gụnyere silicon carbide (SiC) matrix na silicon (Si). Nke mbụ na-enye ihe ndị dị mma n'ibu, na-eyi nguzogide na elu okpomọkụ kwụsie ike,

ebe nke ikpeazụ na-ejuputa pores n'etiti silicon carbide particles iji welie njupụta na nhazi nke ihe onwunwe.

(1) Àgwà:

Nkwụsi ike okpomọkụ dị elu:Oke arụ ọrụ okpomọkụ 1350 ℃.

Yiri nguzogide na nguzogide corrosion:Kwesịrị ekwesị maka ọnọdụ arụ ọrụ siri ike nke oke okpomọkụ, acid, alkali na metal gbazere. ;

Nrụpụta ọkụ dị elu yana ọnụọgụ mgbasawanye thermal dị ala:Thermal conductivity dị elu dị ka 120-200 W / (m·K), na thermal mmụba ọnụọgụ bụ naanị 4.5 × 10⁻ K⁻¹, nke na-egbochi nke ọma thermal cracking na thermal ike ọgwụgwụ. ;

Anti-oxidation:A na-emepụta akwa mkpuchi silica n'elu na oke okpomọkụ iji gbasaa ndụ ọrụ.

(2) Isi ngwaahịa:

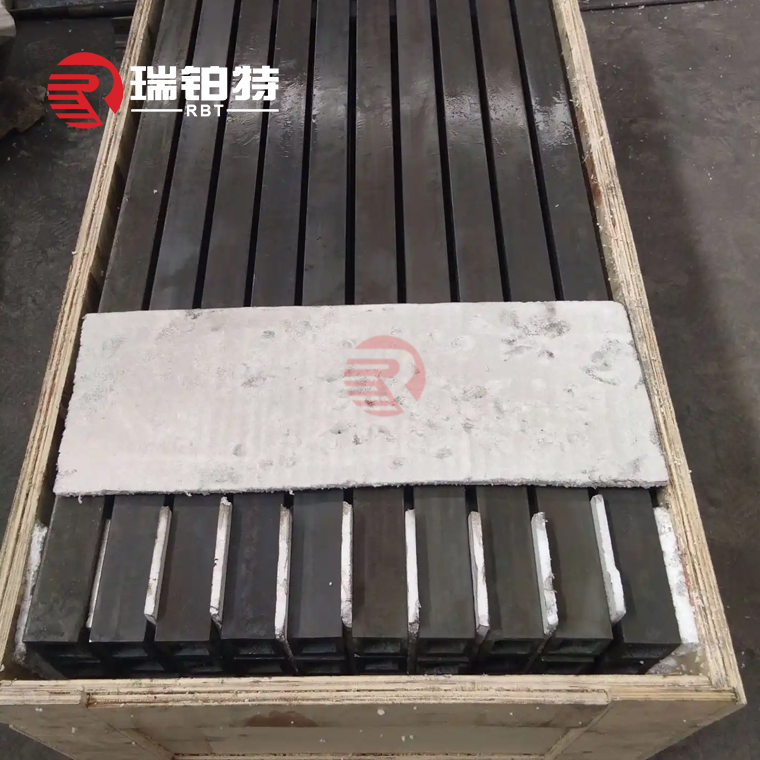

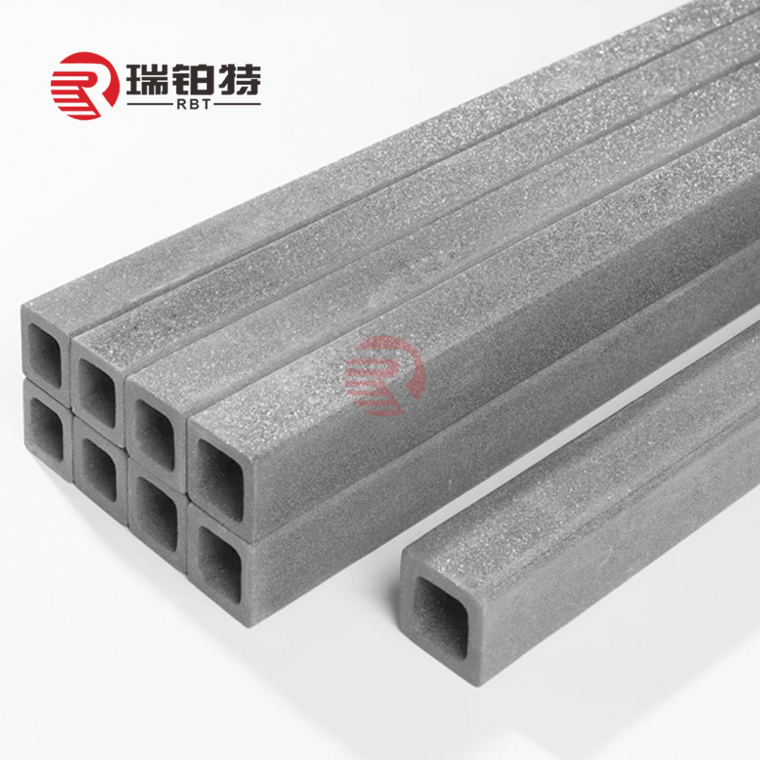

;Silicon carbide beam:eji maka ihe owuwu na-ebu ibu nke ọwara kilns, ụgbọ mmiri kilns na ụlọ ọrụ mmepụta ihe ndị ọzọ, nwere oke nguzogide okpomọkụ dị elu.

;

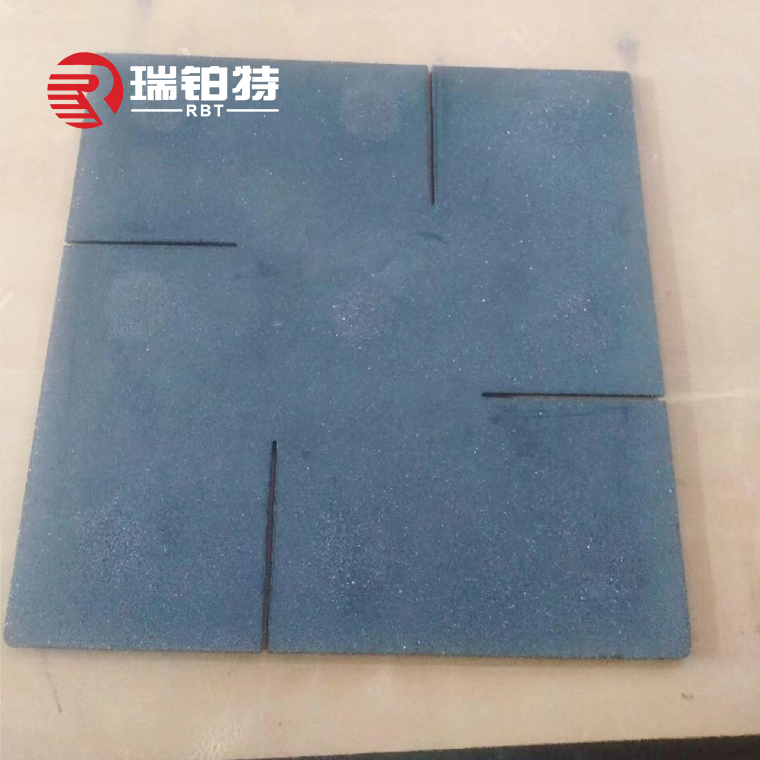

Silicon carbide efere:eji maka ihe ntughari na kilns, nke nwere njirimara oxide bonding. ;

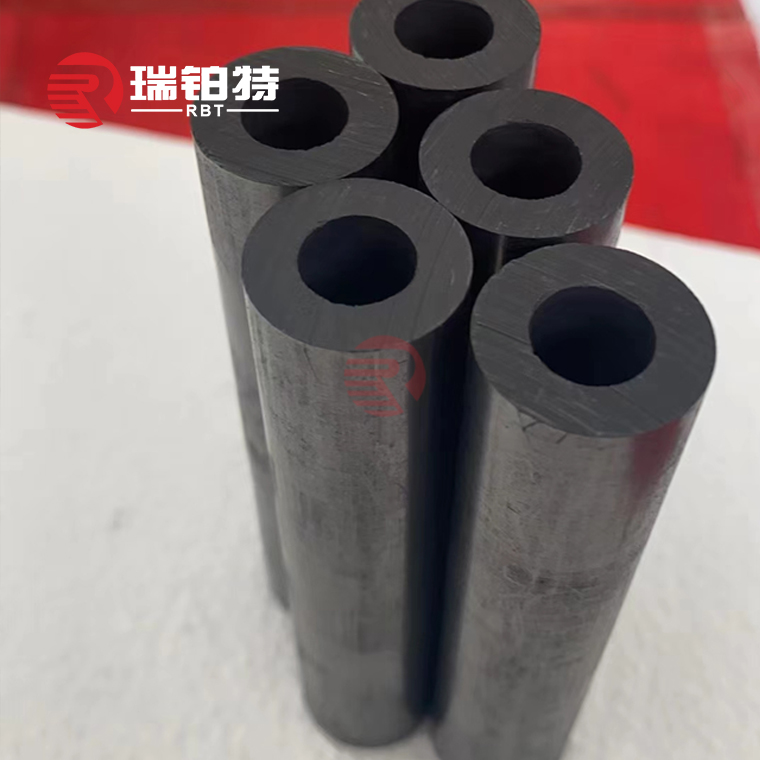

Silicon carbide ọkpọkọ:eji maka ọkpọkọ na arịa dị iche iche dị elu okpomọkụ gburugburu. ;

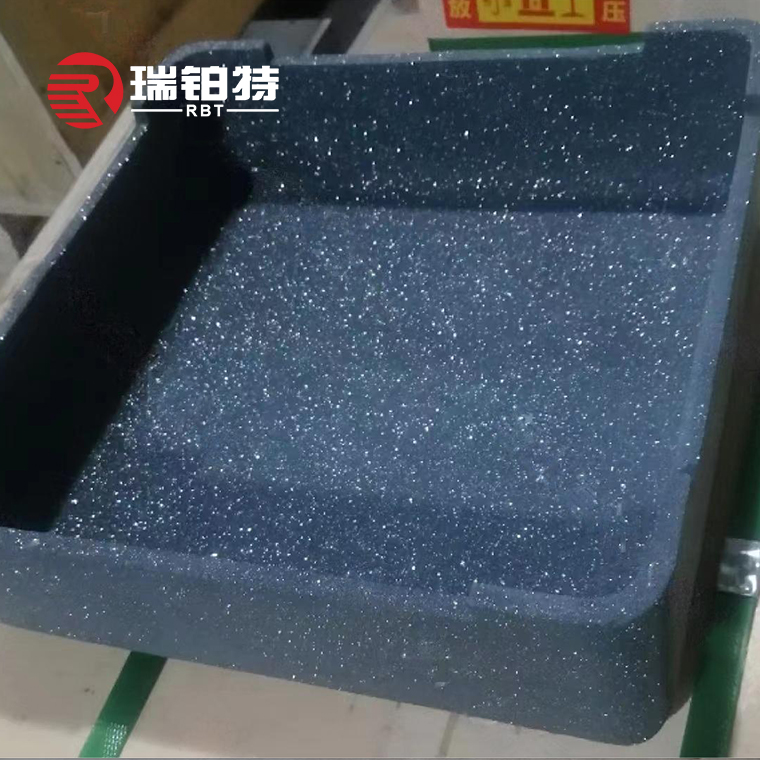

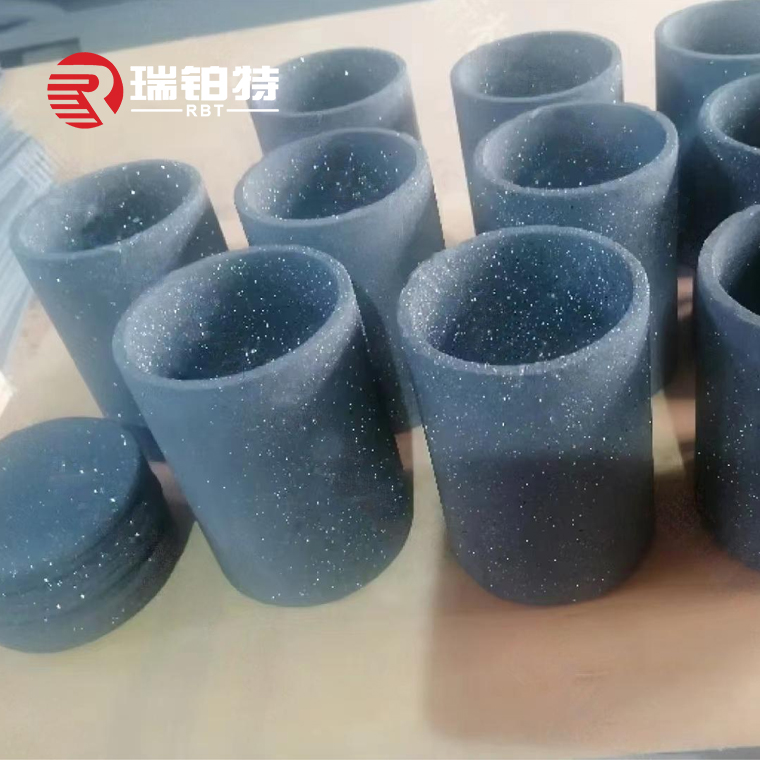

Silicon carbide crucible na sagger:eji maka mgbaze dị elu na nchekwa ihe. ;

Mgbanaka mkpuchi silicon carbide:A na-ejikarị eme ihe n'ọhịa nke ụgbọ ala, ikuku ikuku na ụlọ ọrụ kemịkalụ, ma nwee ike ịnọgide na-arụ ọrụ mkpuchi a pụrụ ịdabere na ya na oke okpomọkụ na gburugburu nrụgide dị elu. ;

Ihe mkpuchi silicon carbide:A na-eji ya eme ihe maka igwe mkpuchi, na njirimara nke mgbochi oxidation, ike mgbanwe okpomọkụ dị elu na ogologo ndụ ọrụ. ;

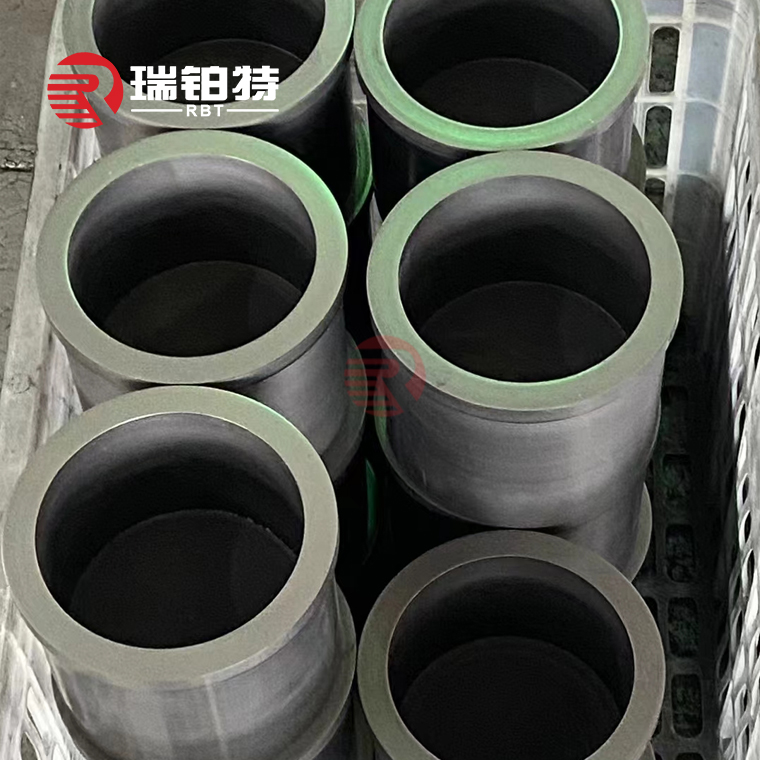

Silicon carbide ọkpọkọ jụrụ oyi:eji maka mpaghara jụrụ oyi nke ihe mkpuchi igwe, na-enwe ezigbo nguzogide oke

oyi na okpomọkụ. ;

Silicon carbide bunner nozzle:eji maka mmanụ dị iche iche, gas na ụlọ ọrụ mmepụta ihe ndị ọzọ, na njirimara nke oke oyi na ikpo ọkụ, na-eyi nkwụsi ike, oke okpomọkụ na-eguzogide, wdg. ;

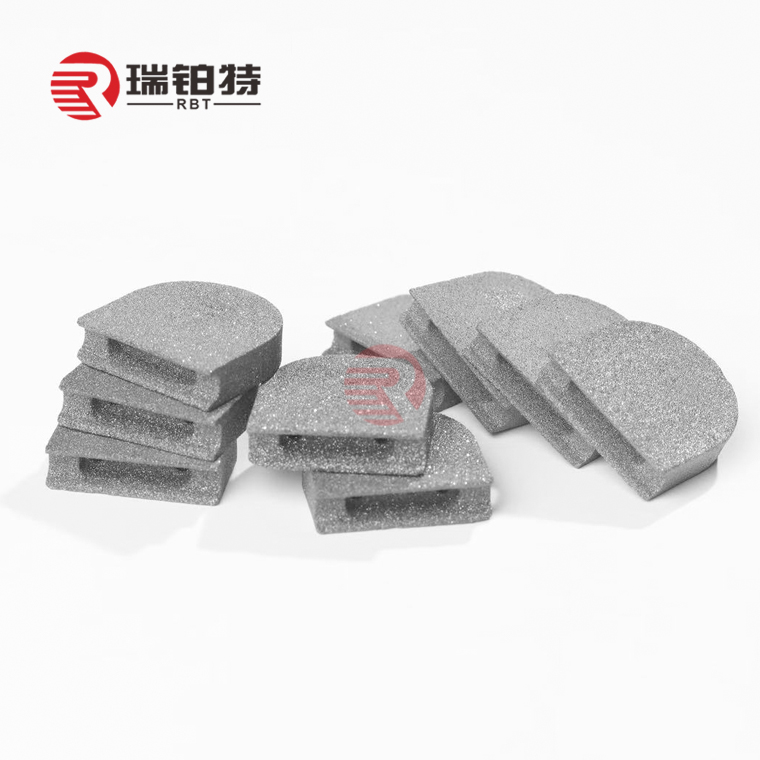

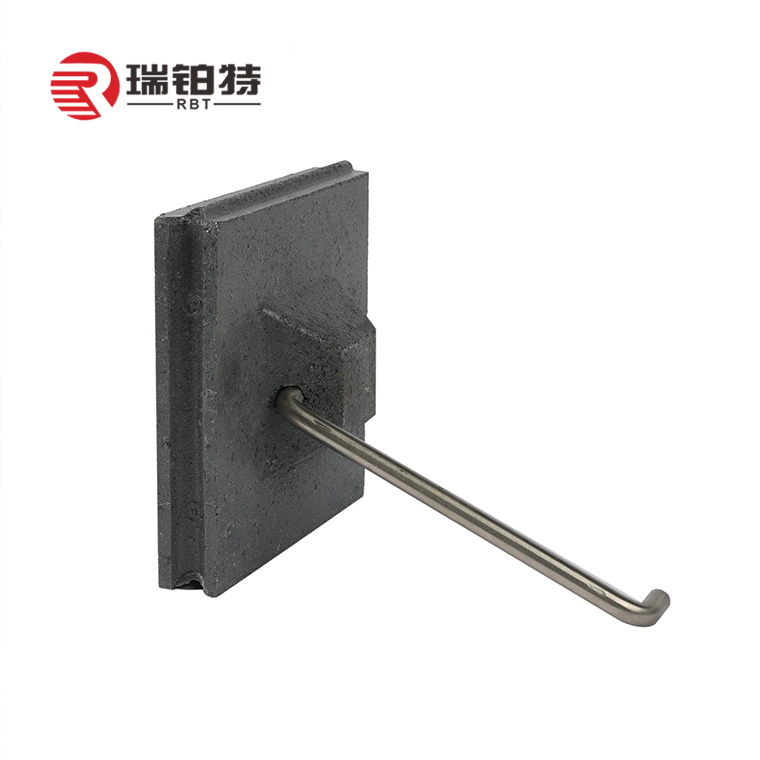

Akụkụ pụrụ iche ahaziri:Mmepụta ahaziri ahazi nke akụkụ dị iche iche nwere ụdị pụrụ iche dịka mkpa ndị ahịa si dị, dị ka efere nwere ụdị azụ, mkpanaka kwụgidere, akụkụ nkwado, wdg.

Foto nkọwa

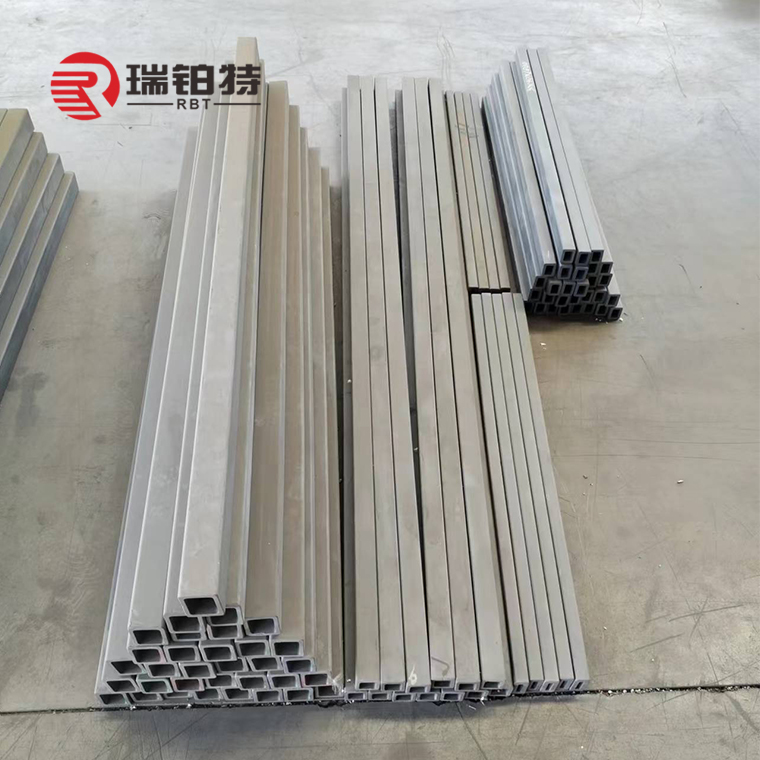

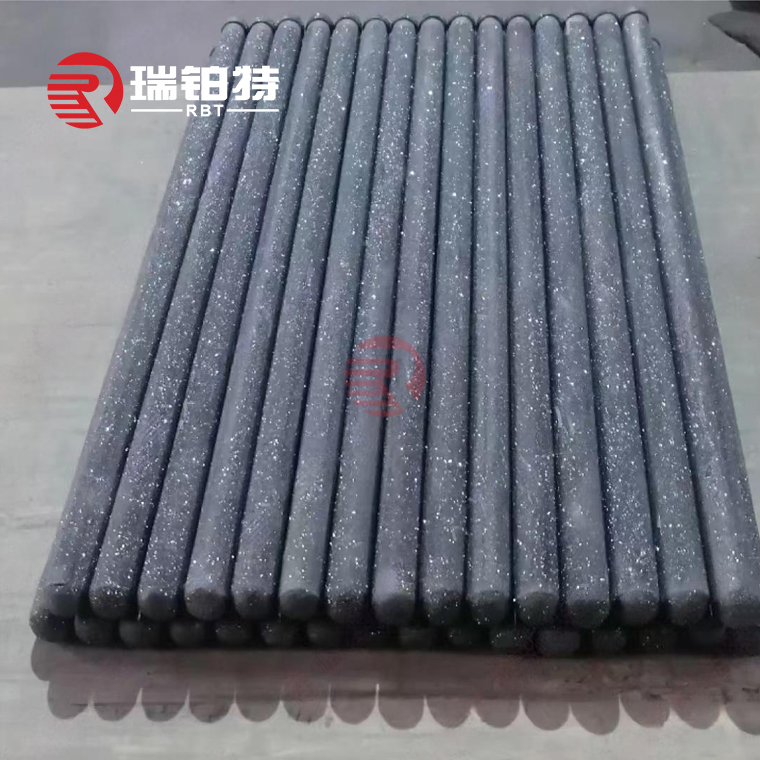

Silicon Carbide Beam

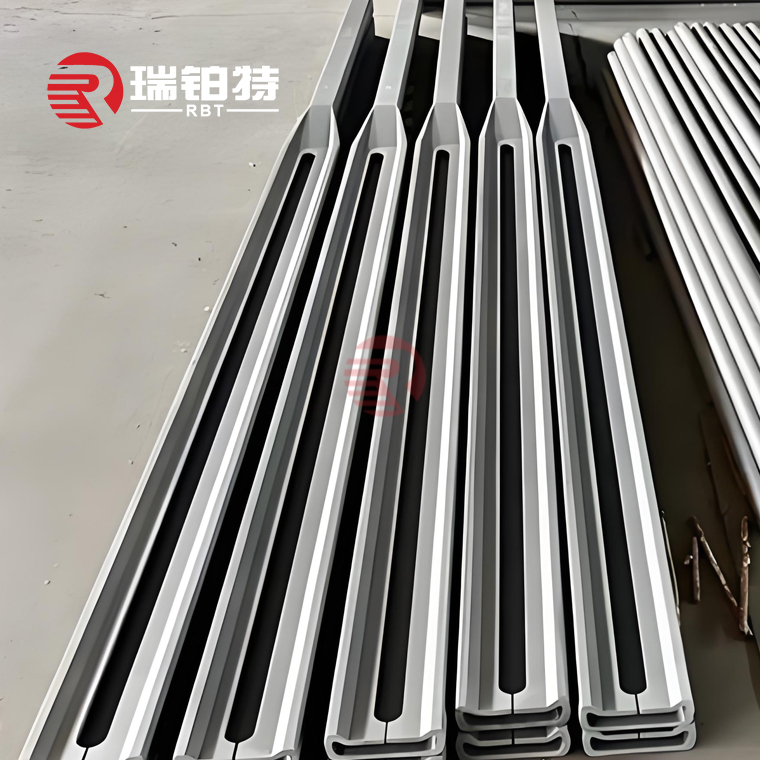

Silicon Carbide Cantilever Paddle

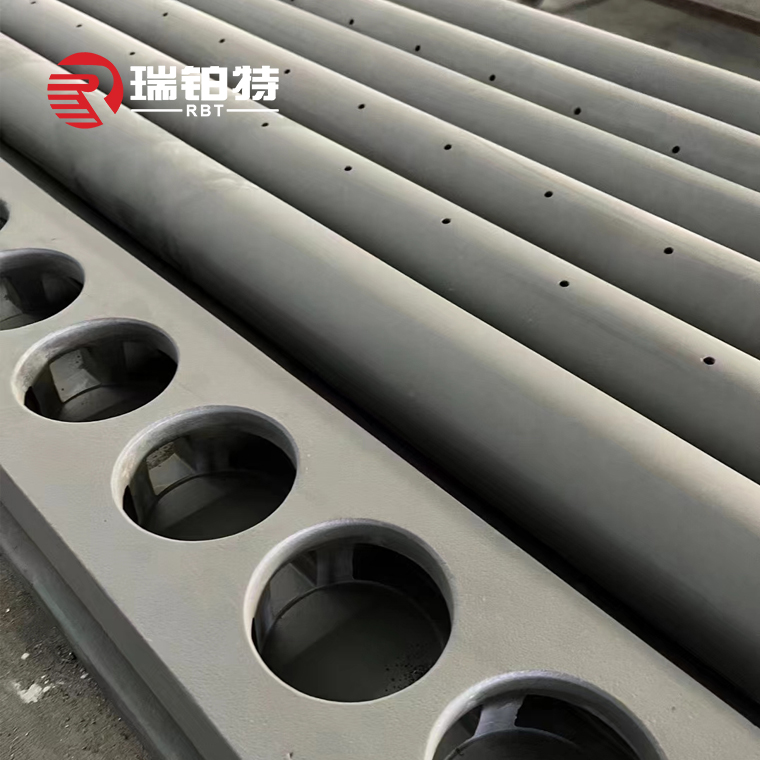

Silicon Carbide Nozzle

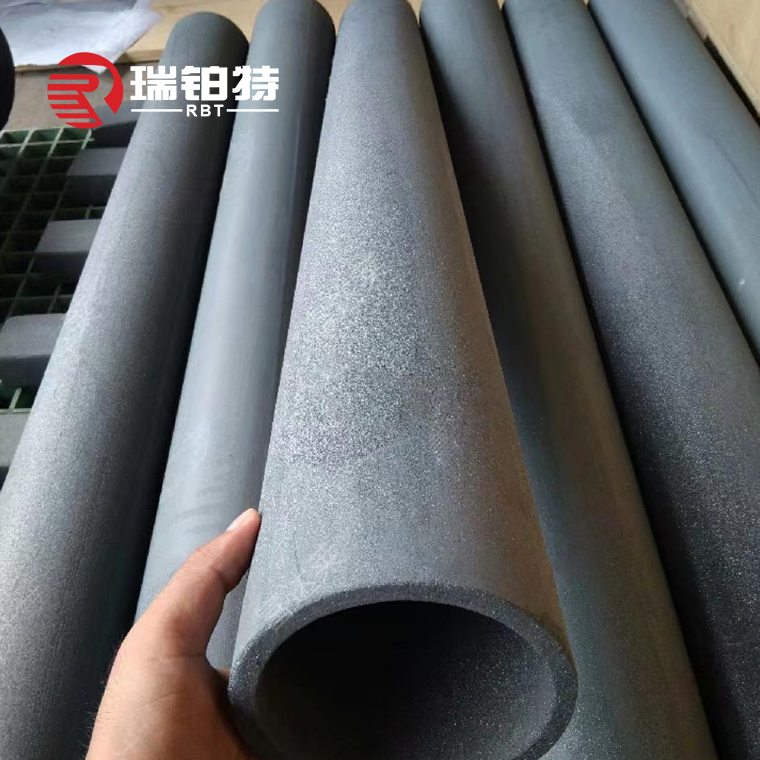

Silicon Carbide Burner Tube

Silicon Carbide jụrụ oyi ọkpọkọ

Silicon Carbide Nozzle

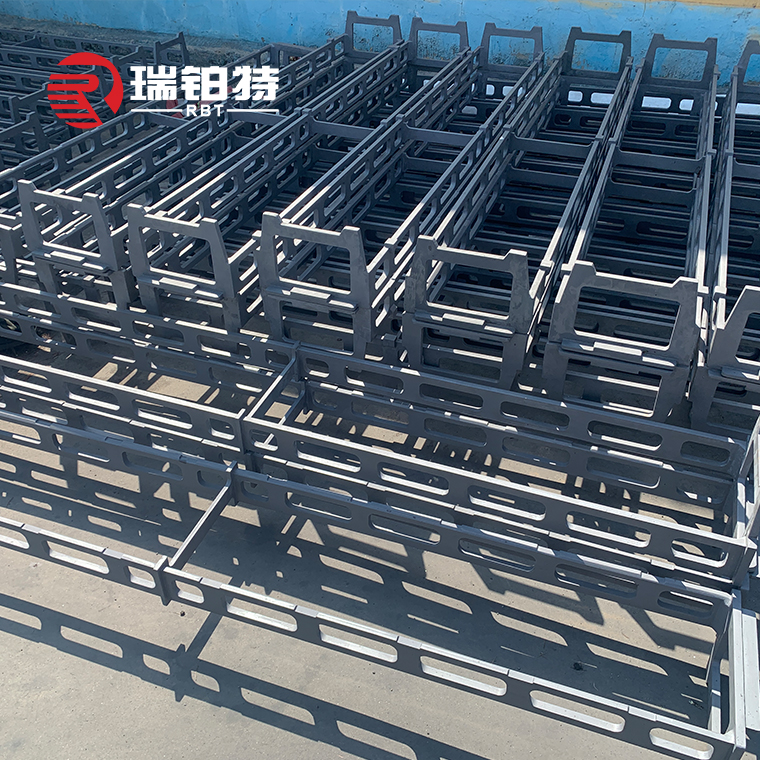

Mpempe ụgbọ mmiri Silicon Carbide

Ihe mkpuchi na-eguzogide iyi

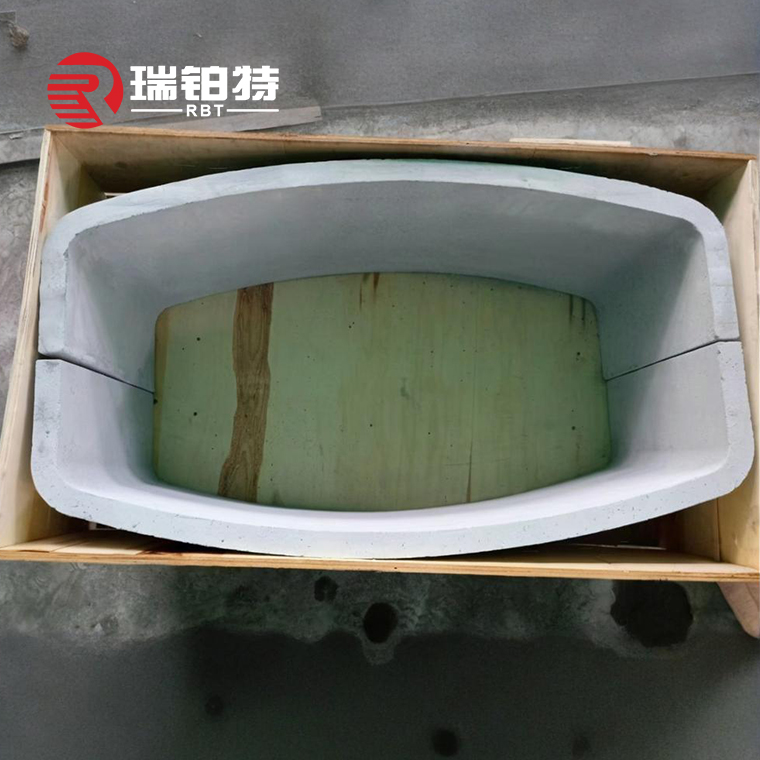

Ụgbọ mmiri Silicon Carbide Wafer

Ndekọ ngwaahịa

| Ngwaahịa RBSiC(SiSiC). | ||

| Ihe | Nkeji | Data |

| Oke okpomọkụ nke ngwa | ℃ | ≤1350 |

| Njupụta | g/cm3 | ≥3.02 |

| Mepee Porosity | % | ≤0.1 |

| Na-ehulata Ike | Mpa | 250 (20 ℃); 280 (1200 ℃) |

| Modul nke Elastictiy | Gpa | 330 (20 ℃); 300 (1200 ℃) |

| Nrụpụta okpomọkụ | W/mk | 45 (1200 ℃) |

| Ọnụego Mgbasawanye okpomọkụ | K-1*10-6 | 4.5 |

| Ike Moh | | 9.15 |

| Acid Alkaline-ihe akaebe | | Magburu onwe |

2. Ngwaahịa silicon carbide na-enweghị nrụgide ( Ngwaahịa SSiC)

Ngwaahịa silicon carbide na-enweghị nrụgide bụ ụdị ihe seramiiki ọgbara ọhụrụ nke a kwadebere site na usoro nhịahụ enweghị nrụgide. Isi ihe mejupụtara ya bụ silicon carbide (SiC), yana agbakwunyere ụfọdụ ihe mgbakwunye. Site na teknụzụ seramiiki dị elu, a na-eme ya ka ọ bụrụ ceramik na-enweghị oghere, enweghị nkebi na enweghị nchekasị.

(1) Àgwà:

Nnukwu nguzogide okpomọkụ:eji nkịtị na 1800 ℃;

Nrụpụta ọkụ dị elu:dakọtara na thermal conductivity nke graphiteihe;

Isi ike dị elu:ike bụ nke abụọ naanị diamond na cubic boron nitride;

Nguzogide corrosion:acid siri ike na alkali siri ike enweghị corrosion na ya, na nguzogide corrosion ya dị mma karịa tungsten carbide na aluminum oxide;

Ibu dị obere:njupụta 3.10g / cm3, nso aluminom;

Enweghị nrụrụ:obere ọnụọgụ mgbasawanye thermal,

Na-eguzogide ujo thermal:ihe nwere ike iguzogide mgbanwe okpomọkụ ngwa ngwa, ihe na-ekpo ọkụ ọkụ, ngwa ngwa ngwa ngwa na kpo oku, ma nwee arụmọrụ kwụsiri ike.

(2) Isi ngwaahịa:

mgbanaka akara:A na-ejikarị ngwaahịa silicon carbide na-enweghị nrụgide eme ihe iji rụpụta mgbanaka mkpuchi na-eguzogide iyi na corrosion na-eguzogide ọgwụ na bearings slide. ;

Akụkụ igwe:Gụnyere nnukwu ọkụ ọkụ, akara igwe, nozzles, valves pneumatic, ahụ mgbapụta, ihe ndozi, wdg.

Ngwa kemịkalụ:A na-eji emepụta ọkpọkọ na-eguzogide corrosion, tankị nchekwa, reactors na akàrà. ;

Ngwa eletrọnịkị:N'ime ụlọ ọrụ ike, a na-eji silicon carbide na-enweghị nrụgide na-emepụta ihe ndị na-eguzogide okpomọkụ, ọkụ ọkụ eletrik na ọkụ ọkụ ọkụ ọkụ. ;

Ngwongwo ụlọ:Dị ka okpokolo agba na-ebu ibu, rollers, ọkụ nozzles, ọkpọkọ jụrụ oyi, wdg na ọwara kilns, ụgbọ mmiri kilns na ndị ọzọ ulo oru kilns. ;

Foto nkọwa

Ihe mgbanaka Silicon Carbide

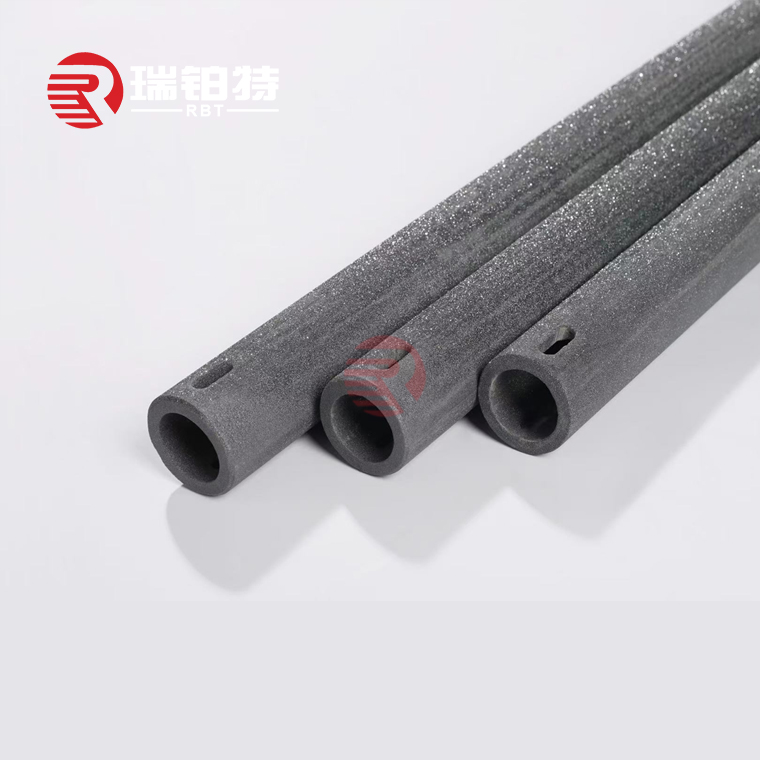

Silicon Carbide Pipe

Silicon Carbide Liners

Silicon Carbide Beam

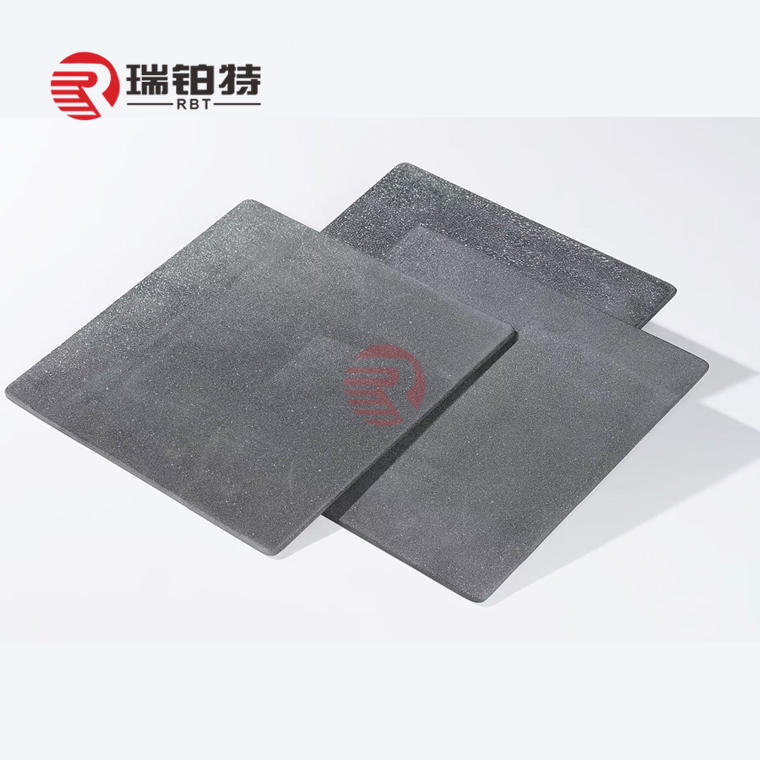

Silicon Carbide efere

Silicon Carbide na-egweri gbọmgbọm

Ndekọ ngwaahịa

| Ngwaahịa SSIC | ||

| Ihe | Nkeji | Nsonaazụ |

| Isi ike | HS | ≥115 |

| Ọnụọgụ porosity | % | <0.2 |

| Njupụta | g/cm3 | ≥3.10 |

| Ike mkpakọ | Mpa | ≥2500 |

| Na-ehulata Ike | Mpa | ≥380 |

| Ọnụọgụ nke Mgbasawanye | 10-6/℃ | 4.2 |

| Ọdịnaya nke SiC | % | ≥98 |

| Free Si | % | <1 |

| Modul na-agbanwe | Gpa | ≥410 |

| Oke okpomọkụ nke ngwa | ℃ | 1400 |

3. Ngwaahịa silicon carbide recrystalized( Ngwaahịa RSiC)

Ngwaahịa Silicon Carbide recrystallized bụ ngwaahịa refractory mere nke silicon carbide dị ọcha dị ka akụrụngwa. Isi ihe ya bụ na ọ nweghị usoro nke abụọ yana 100% α-SiC mejupụtara ya.

(1) Àgwà:

Isi ike dị elu:Isi ike ya bụ nke abụọ na naanị dayamọnd, yana ọ nwere nnukwu ọrụ igwe na ike siri ike. ;

Nguzogide okpomọkụ dị elu:Ọ nwere ike ịnọgide na-enwe ike ịrụ ọrụ na elu okpomọkụ gburugburu ebe obibi na adabara okpomọkụ nso nke 1350 ~ 1600 ℃. ;

Nguzogide corrosion siri ike:Ọ nwere nnukwu nguzogide corrosion na mgbasa ozi dị iche iche ma nwee ike idowe yaihe eji arụ ọrụ ogologo oge n'ọtụtụ ebe na-emebi emebi. ;

Ezigbo nguzogide oxidation:Ọ nwere ezigbo nguzogide oxidation ma nwee ike ịrụ ọrụ nke ọma na oke okpomọkụ. ;

Ezigbo nguzogide ujo thermal:Ọ na-arụ ọrụ nke ọma na gburugburu ebe okpomọkụ na-agbanwe ngwa ngwa ma dabara adaba maka gburugburu akpata oyi. ;

Enweghị mbelata n'oge sintering:Ọ naghị ada mbà n'oge usoro nkwụsịtụ, ọ dịghịkwa nrụgide fọdụrụnụ ga-eme ka nrụrụ ma ọ bụ mgbawa nke ngwaahịa ahụ. Ọ dabara maka nkwadebe nke akụkụ ndị nwere ọdịdị dị mgbagwoju anya na nkenke dị elu.

(2) Isi ngwaahịa:

Akụrụngwa ụlọ ọkụ:A na-ejikarị ya eme ihe maka arịa ụlọ ọkụ, ọ nwere uru nke ịzọpụta ike, na-amụba ụda dị irè nke kiln, na-ebelata oge ịgba ọkụ, na-eme ka mmepụta nke kiln na-arụ ọrụ nke ọma na uru akụ na ụba dị elu. ;

Bunner nozzles:Enwere ike iji ya dị ka isi ọkụ ọkụ ọkụ ma dabara adaba maka gburugburu ebe okpomọkụ dị elu. ;

tubes kpo oku seramiiki:Igwe ọkụ ndị a na-ekpo ọkụ na-erite uru nke nkwụsi ike dị elu na nguzogide corrosion nke silicon carbide recrystallized ma dabara maka ngwa ụlọ ọrụ dị elu dị elu. ;

tubes nchedo akụrụngwa:Karịsịa na ọkụ ikuku, a na-eji ngwaahịa silicon carbide recrystallized dị ka tubes nchebe akụrụngwa nwere ezigbo okpomọkụ dị elu na nguzogide corrosion. ;

Ozu mgbapụta okpomọkụ dị elu, ihe mgbapụta mgbapụta, bearings, ụlọ injin:N'ọhịa nke ụgbọ ala, ụgbọ elu na ụlọ ọrụ ndị agha, a na-eme ka silicon carbide ihe recrystallized n'ime ahụ ọkụ ọkụ dị elu, mgbapụta mgbapụta, bearings na ụlọ engine, wdg, na-eji ohere ha dị elu na-eguzogide okpomọkụ, acid na alkali corrosion resistance na eyi iguzogide. ;

Foto nkọwa

Akụkụ nke Silicon Carbide

Silicon Carbide efere

Silicon Carbide Roller

Silicon Carbide Beam

Tubes Nchekwa Silicon Carbide

Akụrụngwa ụlọ

Silicon Carbide Sagger

Silicon Carbide Crucible

Silicon Carbide efere

Silicon Carbide Lgniter

Silicon Carbide Pipe

Silicon Carbide Burner

4. Silicon nitride bonded silicon carbide ngwaahịa(NSiC Ngwaahịa)

Silicon nitride bonded silicon carbide ngwaahịa bụ ihe a kpụrụ site na ịgbakwunye nchịkọta SiC na ntụ ntụ silicon mmepụta ihe, na-emeghachi omume na nitrogen na okpomọkụ dị elu iji mepụta Si3N4 na ijikọta ya na akụkụ SiC.

(1) Àgwà:

Isi ike dị elu:The Mohs hardness nke silicon nitride bonded silicon carbide ngwaahịa bụ ihe dị ka 9, nke abụọ na diamond, na bụ ihe nwere ike siri ike n'etiti ihe ndị na-abụghị ọla. ;

Ike okpomọkụ dị elu:Na elu okpomọkụ nke 1200-1400 ℃, ike na ike nke ihe onwunwe na-anọgide fọrọ nke nta ka agbanwebeghị, na kacha mma ojiji okpomọkụ nwere ike iru 1650-1750 ℃.

;

Nkwụsi ike okpomọkụ:Ọ nwere obere ọnụọgụ mgbasawanye nke thermal na ịdị elu thermal conductivity, ọ naghị adị mfe ịmepụta nrụgide thermal, nwere ezigbo nkwụsi ike ujo na nkwụsi ike, ma dabara adaba maka oke oyi na gburugburu ebe ọkụ. ;

Nkwụsi ike kemịkalụ:Ọ na-eguzogide corrosion na ọxịdashọn na-eguzogide, ma nwee ike ịnọgidesi ike na gburugburu kemịkalụ dị iche iche. ;

Yiri nguzogide:Ọ nwere nguzogide iyi dị mma ma dabara adaba maka ngwa ụlọ ọrụ dị iche iche nwere oke ike.

(2) Isi ngwaahịa:

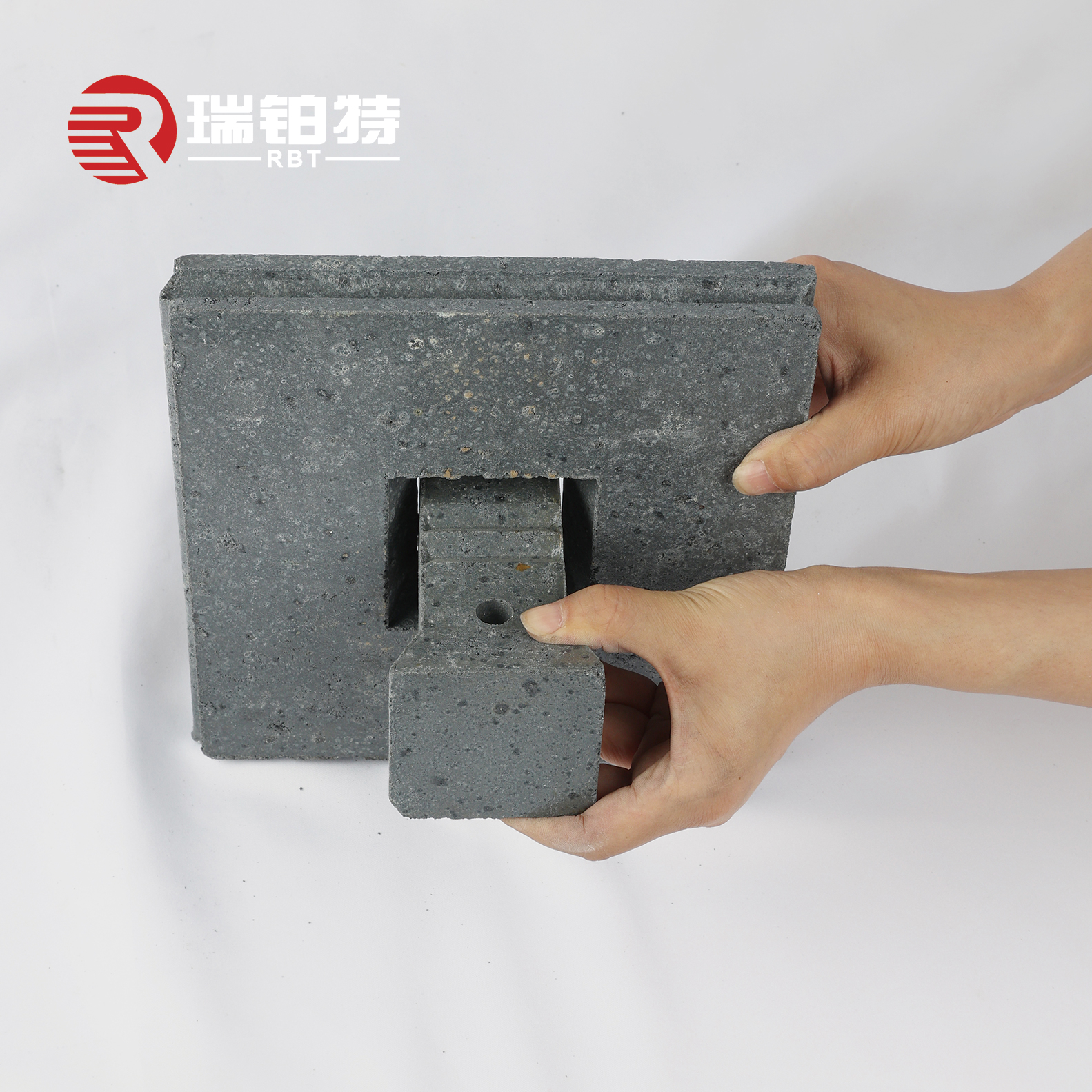

Brick ndị na-emegharị emegharị:A na-eji ya eme ihe na aluminom electrolytic, igwe ọkụ na-agbawa ígwè, ọkụ arc na-ekpuchi mmiri na ụlọ ọrụ ndị ọzọ, nwere njirimara nke nguzogide okpomọkụ dị elu, nguzogide corrosion, na nguzogide mbuze.

Ngwongwo ụlọ:eji maka wheel egweri seramiiki, igwe eletrik eletrik dị elu, kilns ụlọ ọrụ, wdg, nwere ikike ibu dị mma na nguzogide okpomọkụ dị elu.

Ngwaahịa nwere ụdị pụrụ iche:eji na-abụghị nke metallurgical nkedo, thermal ike, submerged arc furnace na ndị ọzọ ọrụ, na àgwà nke eyi nguzogide na elu okpomọkụ iguzogide.

Akụkụ refractory:gụnyere tubes nchebe thermocouple, tubes riser, uwe aka ọkụ, wdg, nke a na-eji na ọkụ ọkụ dị elu na ikuku dị iche iche, na-enwe mmetụta dị elu nke okpomọkụ na nkwụsị corrosion.

Foto nkọwa

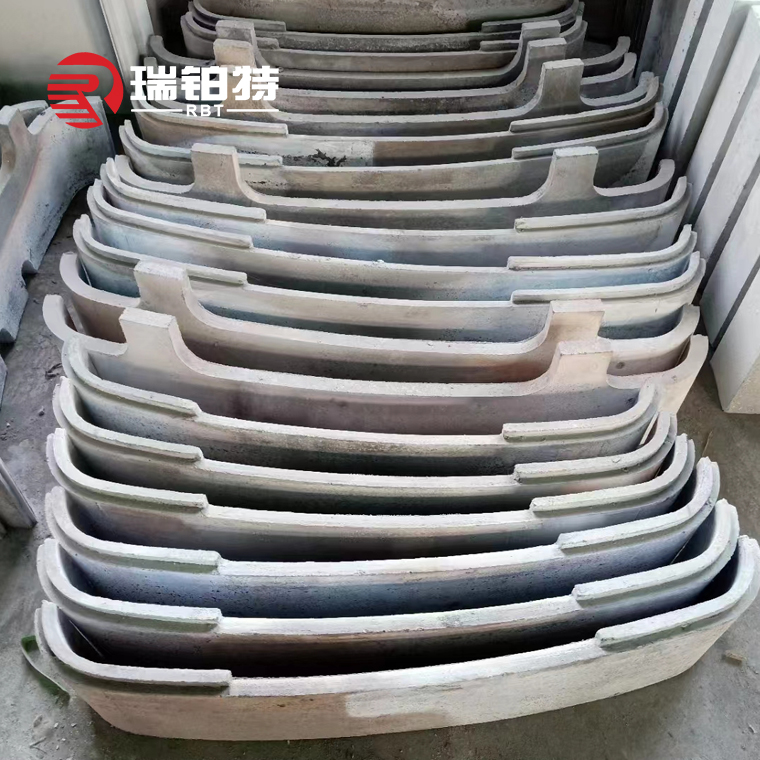

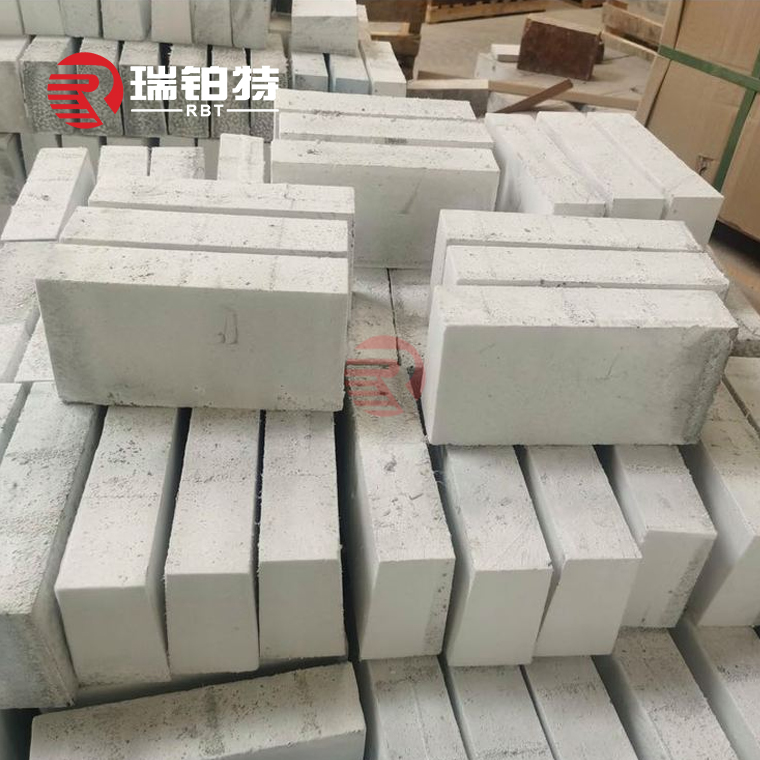

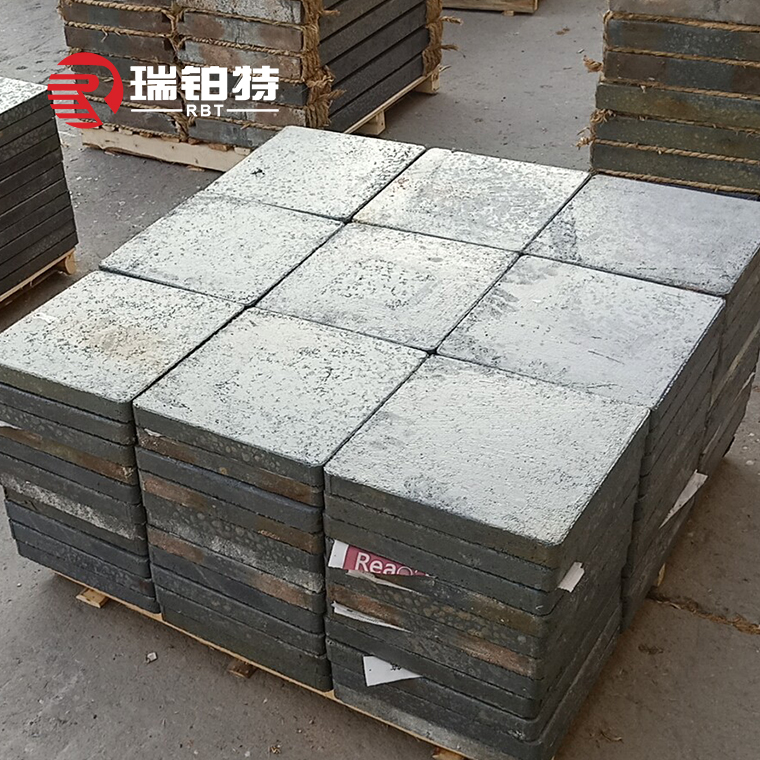

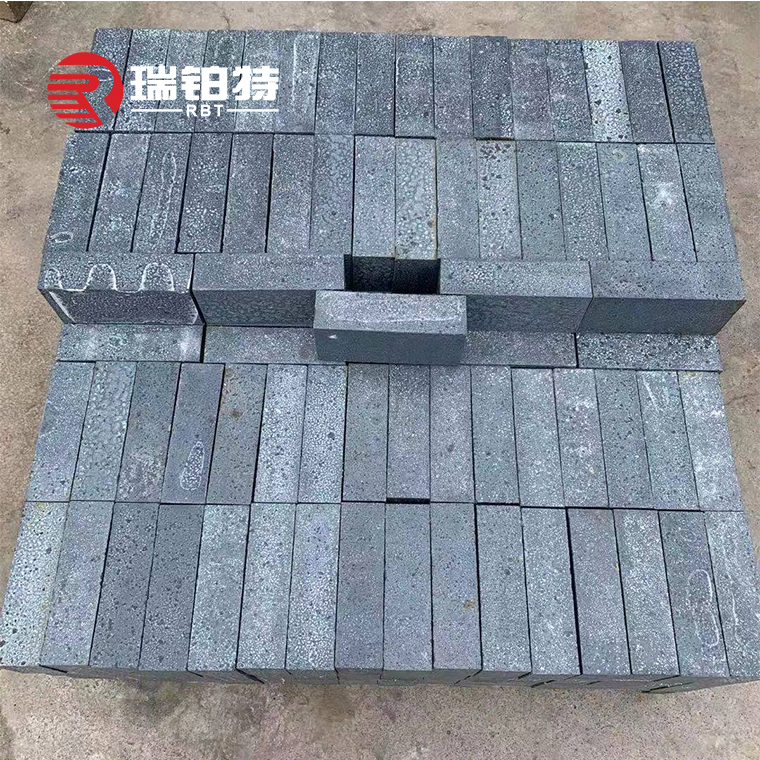

Efere Ebere Silicon Carbide

Efere Ebere Silicon Carbide

Efere Ebere Silicon Carbide

Efere Ebere Silicon Carbide

Efere Ebere Silicon Carbide

Silicon Carbide Radiation Tubes

Silicon Carbide Pipe

Efere Ebere Silicon Carbide

Akụkụ nke Silicon Carbide

Tubes Nchekwa Silicon Carbide

Silicon Carbide efere

Brick Silicon Carbide

5. ngwaahịa silicon carbide na-ejikọta oxide

A na-emepụta ngwaahịa silicon carbide na-ejikọta oxide site na ịgwakọta ụmụ irighiri silicon carbide na ntụ ntụ oxide (dị ka silicon dioxide ma ọ bụ mullite), ịpị na ịgbanye na oke okpomọkụ. Ihe e ji mara ya bụ na n'oge nhazi na iji usoro, a na-ekpuchi ihe nkiri oxide na ihe ndị dị na silicon carbide, nke na-eme ka nkwụsị oxidation dịkwuo mma na ike okpomọkụ dị elu.

Ọ nwere njiri mara nke ike mgbanwe dị elu nke okpomọkụ dị elu, nkwụsi ike dị mma nke thermal, conductivity high thermal, na-eyi nguzogide na ike na-eguzogide ikuku dị iche iche, ma bụrụ ihe dị mma na-echekwa ike maka ọkụ ọkụ.

(2) Isi ngwaahịa:

Ngwaahịa silicon dioxide bonded silicon carbide ngwaahịa:Ngwaahịa a na-eji silicon dioxide (SiO2) dị ka akụkụ njikọ. Ọtụtụ mgbe 5% ~ 10% nke silicon dioxide ntụ ntụ ma ọ bụ quartz ntụ ntụ na-agwakọta ya na silicon carbide (SiC). Mgbe ụfọdụ, a na-agbakwunye mgbanwe. Mgbe ịpịchara ma na-akpụ, a na-agba ya ọkụ na kiln izugbe. Ihe e ji mara ya bụ na n'oge a na-agbapụ ma na-eji ya eme ihe, a na-ekpuchi ihe nkiri silicon dioxide na ihe ndị dị na silicon carbide, nke na-eme ka nkwụsị nke oxidation na ike dị elu. Ngwaahịa a na ọtụtụ-eji na kiln shelves maka firing poselin (> 1300 ℃), na ya ọrụ ndụ bụ ihe karịrị

okpukpu abụọ nke ngwaahịa silicon carbide jikọtara ụrọ. ;

Ngwaahịa silicon carbide jikọtara ọnụ:Ngwaahịa a na-agbakwụnye ntụ ntụ α-Al2O3 na silicon dioxide ntụ ntụ na ihe ndị na-emepụta silicon carbide. Mgbe ịpịchara na ịmepụta, a na-ejikọta Al2O3 na SiO2 iji mepụta mullite n'oge usoro nhazi. N'oge a na-eji ya, silicon dioxide kpụrụ site na oxidation nke silicon carbide na-etolite mullite na Al2O3. Nke a ihe onwunwe nwere ezigbo thermal ujo kwụsie ike na ọtụtụ ebe na-emepụta nke poselin saggers na shelves.

Foto nkọwa

Silicon Carbide efere

Brick Silicon Carbide

Silicon Carbide efere

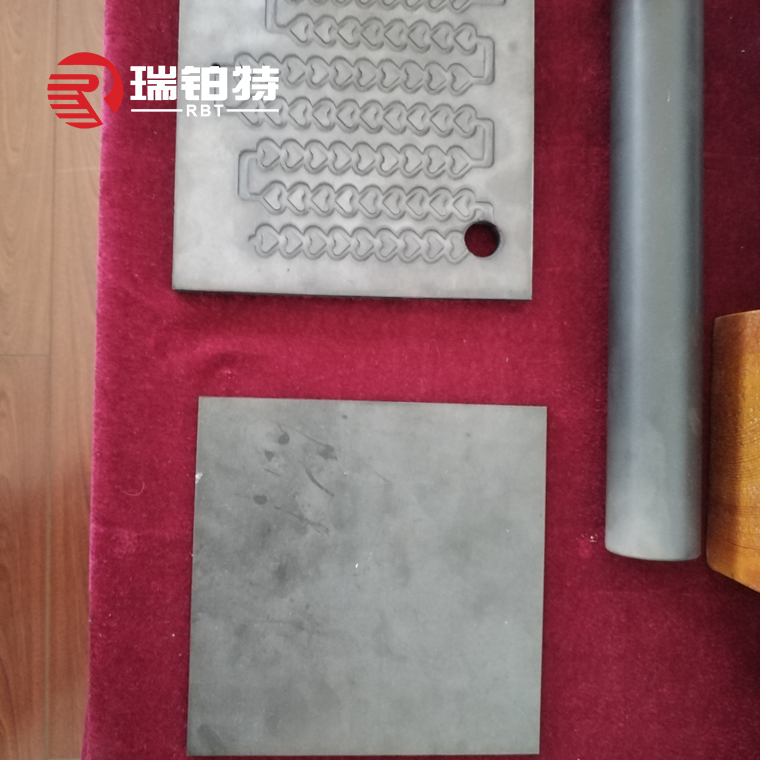

SiC Microcrystalline Pipe

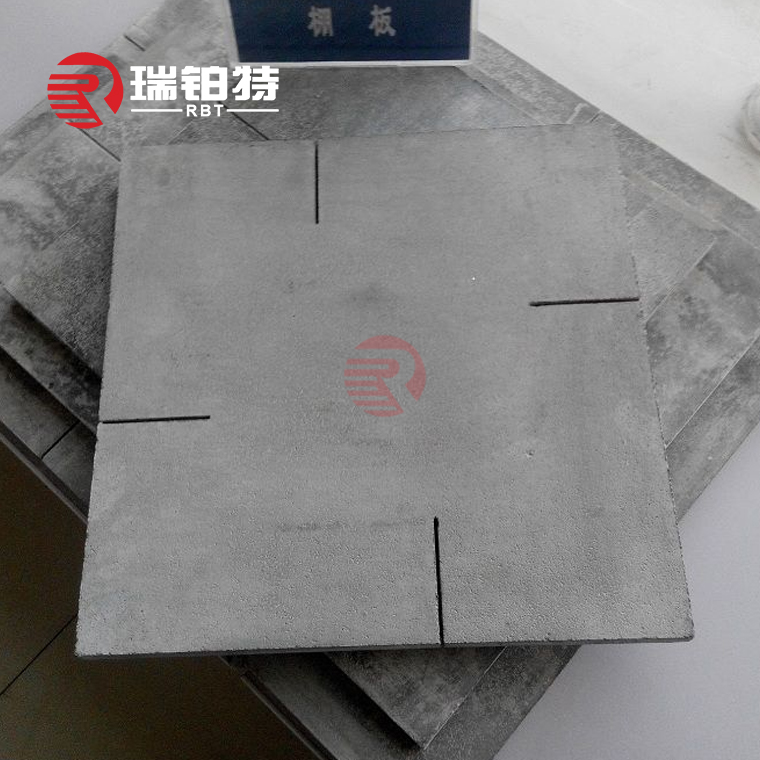

SiC Microcrystalline Board

SiC Microcrystalline Board

Nkọwapụta Ụlọ ọrụ

Ụgwọ nke ụlọ ọrụ Shandong Robert New Material Co., Ltd.dị na Zibo City, Shandong Province, China, nke bụ isi ihe na-emepụta ihe na-emepụta ihe. Anyị bụ ụlọ ọrụ ọgbara ọhụrụ nke na-ejikọta nyocha na mmepe, mmepụta, ire ahịa, imewe na ihe owuwu ụlọ, nkà na ụzụ, na ihe ndị na-emepụta ihe na-ebupụ. Anyị nwere akụrụngwa zuru oke, teknụzụ dị elu, ike teknụzụ siri ike, ogo ngwaahịa dị mma, na aha ọma. Ụlọ ọrụ anyị na-ekpuchi ihe karịrị 200 acres na mmepụta kwa afọ nke ihe na-emegharị ihe na-eme ka ọ dị ihe dị ka tọn 30000 na ihe na-emepụta ihe na-adịghị ahụ bụ 12000 tọn.

Ngwaahịa anyị bụ isi nke ihe refractory gụnyere:alkaline refractory ihe; aluminum silicon refractory ihe; ihe ntughari na-enweghị ọdịdị; ihe mkpuchi thermal refractory; ihe ngbanwe pụrụ iche; ihe na-arụ ọrụ refractory maka usoro nkedo na-aga n'ihu.

Ajụjụ a na-ajụkarị

Achọrọ enyemaka? Jide n'aka na ịga na forums nkwado anyị maka azịza nye ajụjụ gị!

Anyị bụ ezigbo emeputa, ụlọ ọrụ anyị bụ ọkachamara na-emepụta ihe refractory maka ihe karịrị afọ 30. Anyị na-ekwe nkwa ịnye ọnụahịa kacha mma, ọrụ izizi ahịa na mgbe irechara.

Maka usoro mmepụta nke ọ bụla, RBT nwere usoro QC zuru ezu maka ihe mejupụtara kemịkalụ na ihe anụ ahụ. Na anyị ga-anwale ngwongwo ndị ahụ, a ga-ebufekwa akwụkwọ ikike na ngwaahịa. Ọ bụrụ na ị nwere ihe pụrụ iche chọrọ, anyị ga-agbalị ike anyị niile ịnabata ha.

Dabere na ọnụ ọgụgụ, oge nnyefe anyị dị iche. Mana anyị na-ekwe nkwa na anyị ga-ebufe ngwa ngwa o kwere omume na ịdị mma ejiri n'aka.

N'ezie, anyị na-enye free samples.

Ee, n'ezie, ị na-anabata ileta RBT ụlọ ọrụ na anyị ngwaahịa.

Enweghị oke, anyị nwere ike ịnye ndụmọdụ na ngwọta kachasị mma dịka ọnọdụ gị si dị.

Anyị na-eme ihe refractory ihe karịrị afọ 30, anyị nwere nkwado teknụzụ siri ike na ahụmahụ bara ụba, anyị nwere ike inyere ndị ahịa aka ịmepụta kilns dị iche iche ma nye otu nkwụsị ọrụ.