Ngwaahịa SSIC

Ozi ngwaahịa

| NgwaahịaAha | Ngwaahịa SSIC ( Ngwaahịa Silicon Carbide na-eme ikuku) |

| Nkọwa | 1. Ihe a bụ ngwaahịa seramiiki siri ike nke SiC mere site na nkwụsịtụ na-enweghị nrụgide nke nnukwu arụmọrụ sub-micron SiC ntụ ntụ.Ọ nweghị silicon n'efu ma nwee ọmarịcha ọka. 2. Ọ bụ ugbu a họọrọ n'ozuzu ihe maka mba na ụlọ n'ichepụta n'ibu akara yiri mgbaaka, sandblasting nozzles, mgbo agha, magnetik nfuli, na mkpọ mgbapụta mmiri. 3. Ọ na-adabara karịsịa maka iji na-ebugharị mgbasa ozi corrosive dị ka acid siri ike na alkali siri ike. |

| Njirimara | 1. Ike dị elu, ike siri ike, na-eyi nguzogide, njupụta ruo 3.1kg / m3. 2. Ọrụ attenuation dị elu, mgbasawanye ọkụ dị ala, nkwụsị ọkụ dị elu, nnukwu okpomọkụ na-eguzogide. 3. Nkwụsi ike nke kemịkalụ, nguzogide corrosion, karịsịa hydrofluoric acid resistance. 4. elu-okpomọkụ eguzogide, kacha arụ ọrụ okpomọkụ ruo 1380 ℃. 5. Ogologo ndụ ọrụ ma belata ọnụ ahịa ntinye ego n'ozuzu ya. |

Ndekọ ngwaahịa

| Ngwaahịa SSIC | ||

| Ihe | Nkeji | Nsonaazụ |

| Isi ike | HS | ≥115 |

| Ọnụọgụ porosity | % | <0.2 |

| Njupụta | g/cm3 | ≥3.10 |

| Ike mkpakọ | Mpa | ≥2500 |

| Na-ehulata Ike | Mpa | ≥380 |

| Ọnụọgụ nke Mgbasawanye | 10-6/℃ | 4.2 |

| Ọdịnaya nke SiC | % | ≥98 |

| Free Si | % | <1 |

| Modul na-agbanwe | Gpa | ≥410 |

| Okpomọkụ | ℃ | 1400 |

Foto nkọwa

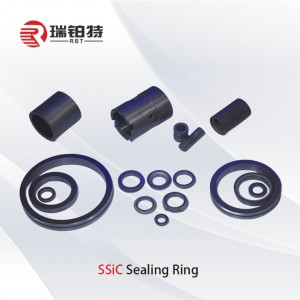

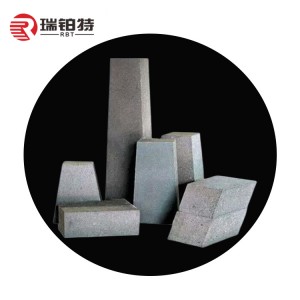

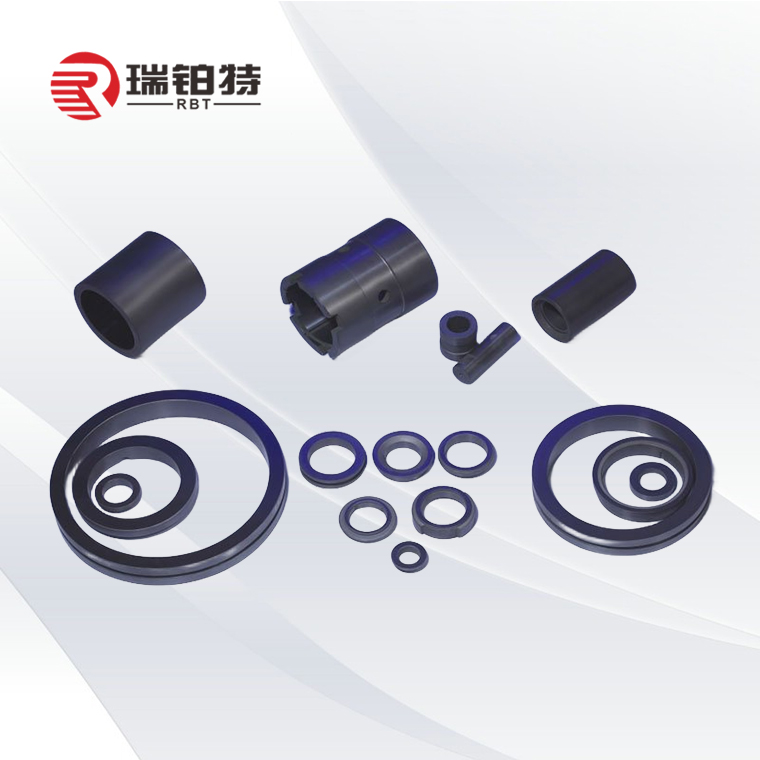

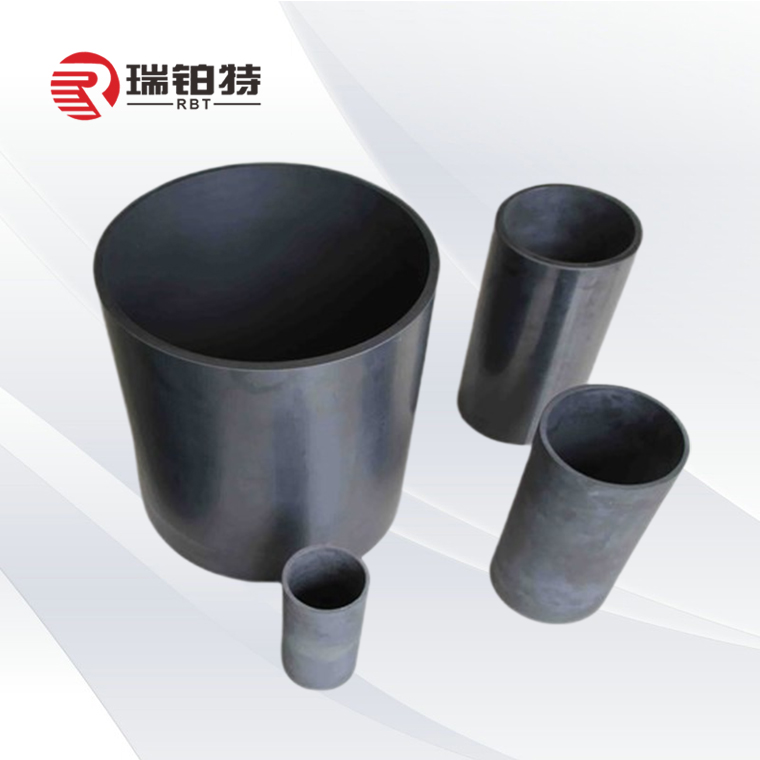

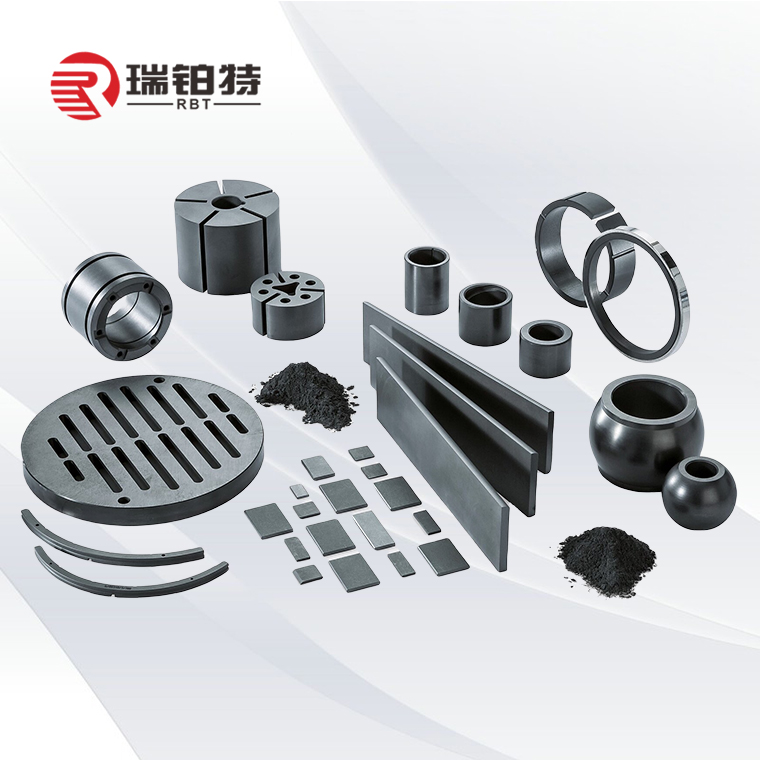

Mgbanaka akara SSSiC

SSiC ọkụ

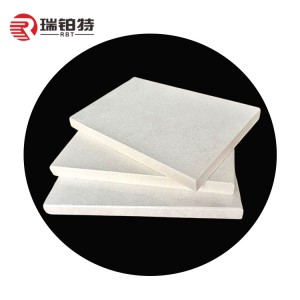

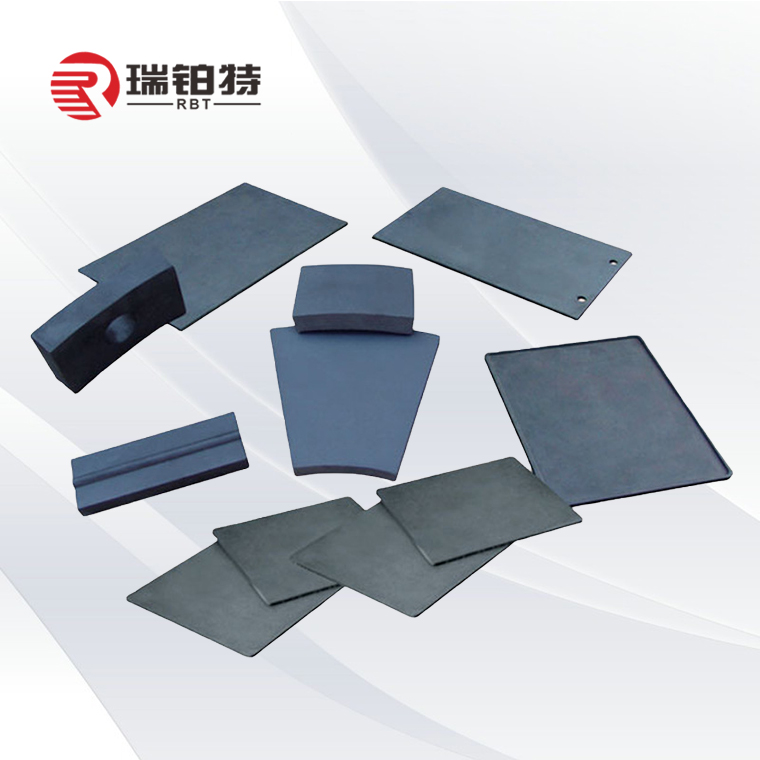

SSiC Tray

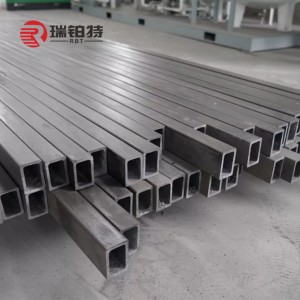

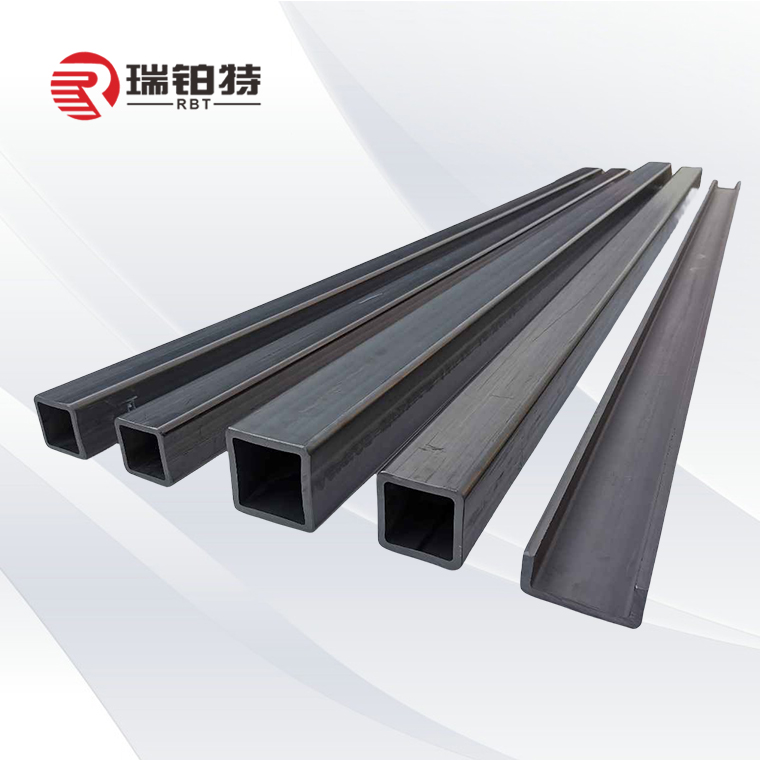

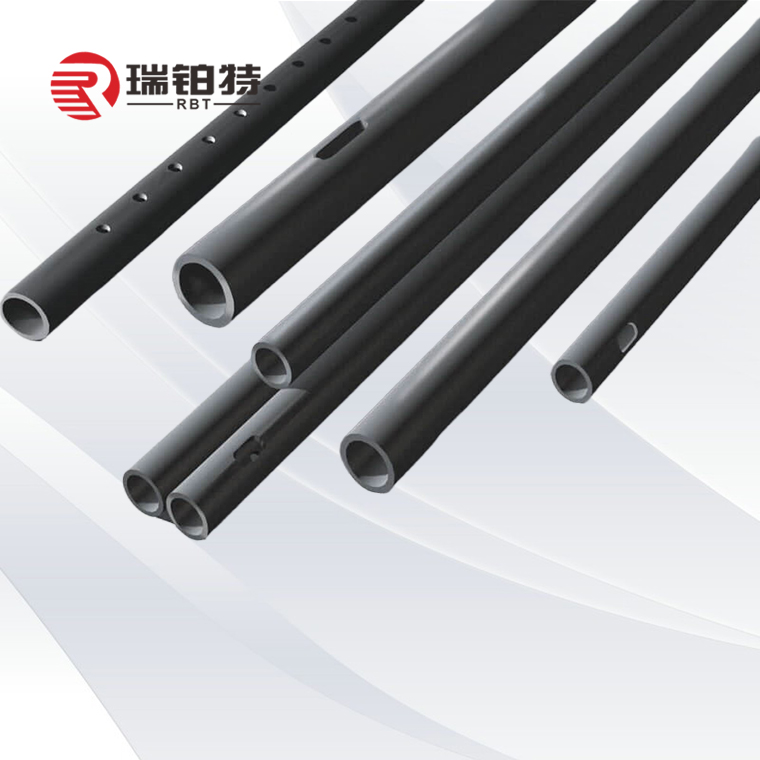

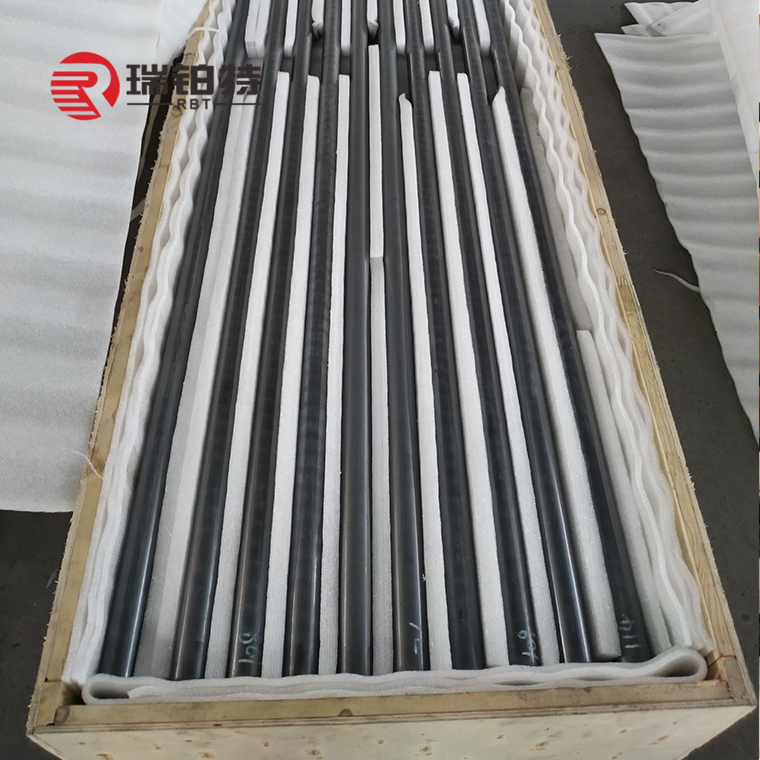

SSiC Roller

SSiC na-egwe ọka

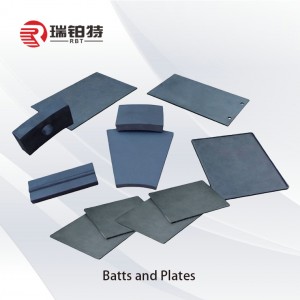

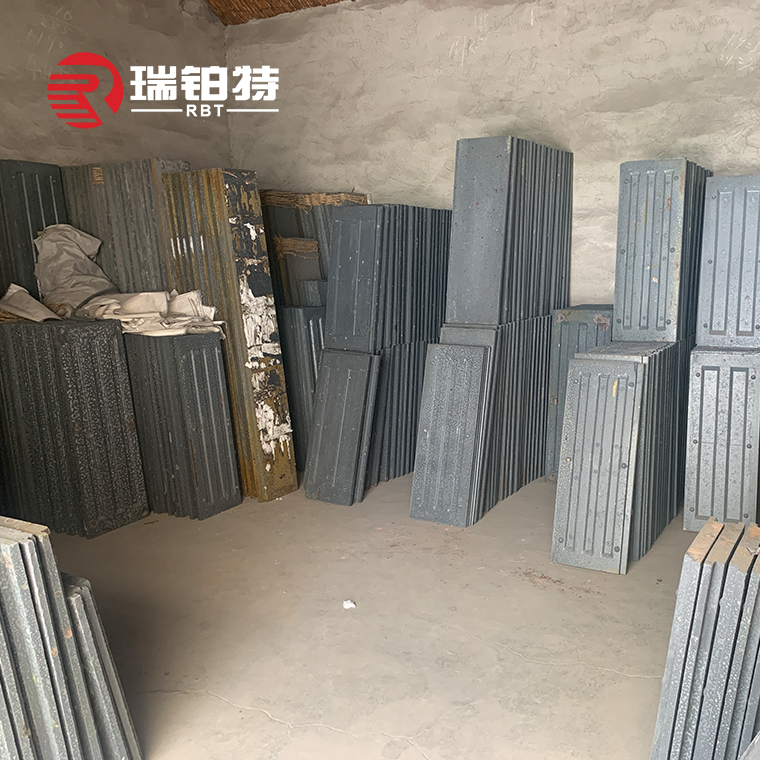

Batts na efere SSSiC

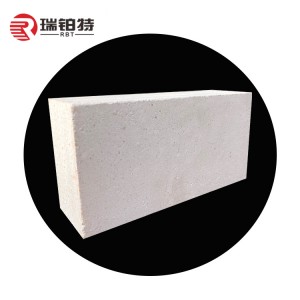

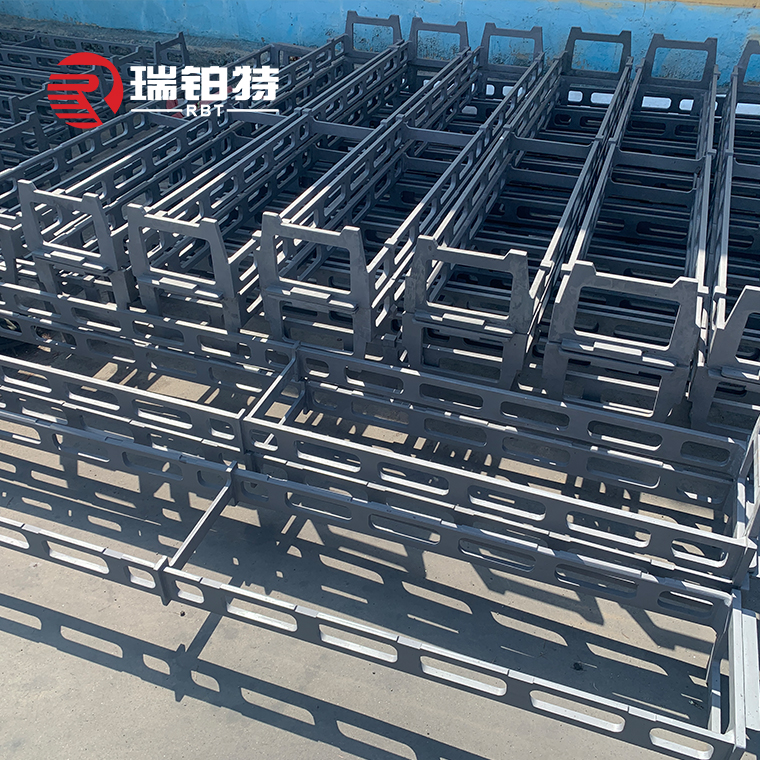

Akụkụ ahaziri SSSiC

Ngwugwu & Ụlọ nkwakọba ihe

Ajụjụ a na-ajụkarị

Achọrọ enyemaka?Jide n'aka na ịga na forums nkwado anyị maka azịza nye ajụjụ gị!

Anyị bụ ezigbo emeputa, ụlọ ọrụ anyị bụ ọkachamara na-emepụta ihe refractory maka ihe karịrị afọ 30.Anyị na-ekwe nkwa ịnye ọnụahịa kacha mma, ọrụ izizi ahịa na mgbe irechara.

Maka usoro mmepụta nke ọ bụla, RBT nwere usoro QC zuru ezu maka ihe mejupụtara kemịkalụ na ihe anụ ahụ.Na anyị ga-anwale ngwongwo ndị ahụ, a ga-ebufekwa akwụkwọ ikike na ngwaahịa.Ọ bụrụ na ị nwere ihe pụrụ iche chọrọ, anyị ga-agbalị ike anyị niile ịnabata ha.

Dabere na ọnụ ọgụgụ, oge nnyefe anyị dị iche.Ma anyị na-ekwe nkwa ibupu ngwa ngwa o kwere omume na mma ekwe nkwa.

N'ezie, anyị na-enye free samples.

Ee, n'ezie, ị na-anabata ileta RBT ụlọ ọrụ na anyị ngwaahịa.

Enweghị oke, anyị nwere ike ịnye ndụmọdụ na ngwọta kachasị mma dịka ọnọdụ gị si dị.

Anyị na-eme ihe refractory ihe karịrị afọ 30, anyị nwere nkwado teknụzụ siri ike na ahụmahụ bara ụba, anyị nwere ike inyere ndị ahịa aka ịmepụta kilns dị iche iche ma nye otu nkwụsị ọrụ.