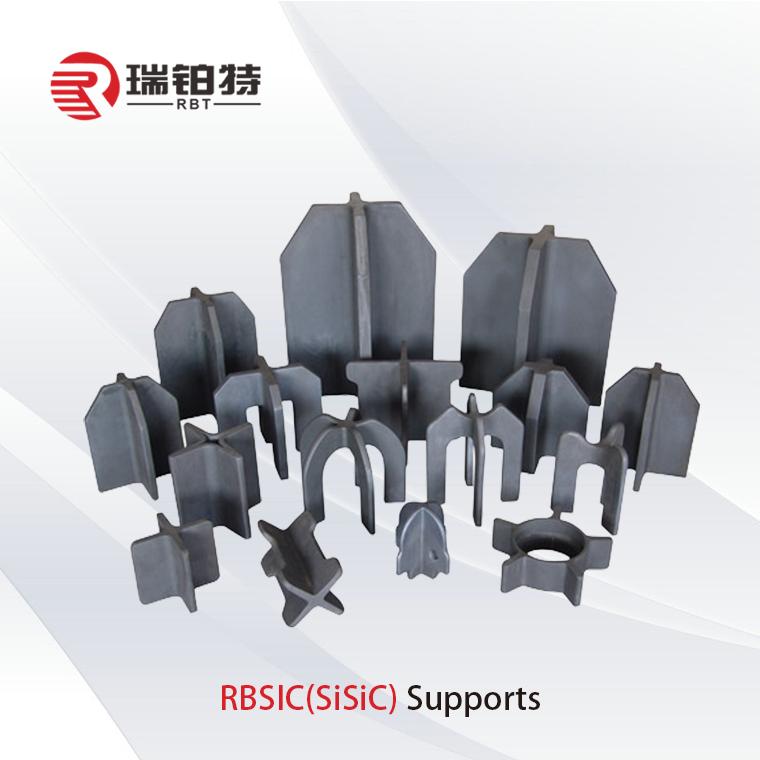

Ngwaahịa RBSiC(SiSiC).

Ozi ngwaahịa

| NgwaahịaAha | Ngwaahịa RBSIC(SiSiC)( Ngwaahịa Silicon Carbide na-emeghachi omume) |

| Nkọwa | Siliconized SiC bụ mmeghachi omume silicon nke agwakọtara n'otu n'otu ma tinye ya na obere irighiri SiC, ntụ ntụ carbon na ihe mgbakwunye n'ogo iji mepụta SiC wee jikọta ya na SiC, silicon ngafe na-ejuputa oghere iji nweta ihe seramiiki buru ibu. |

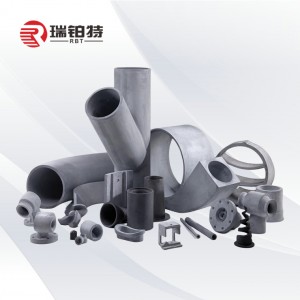

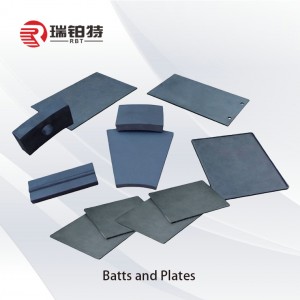

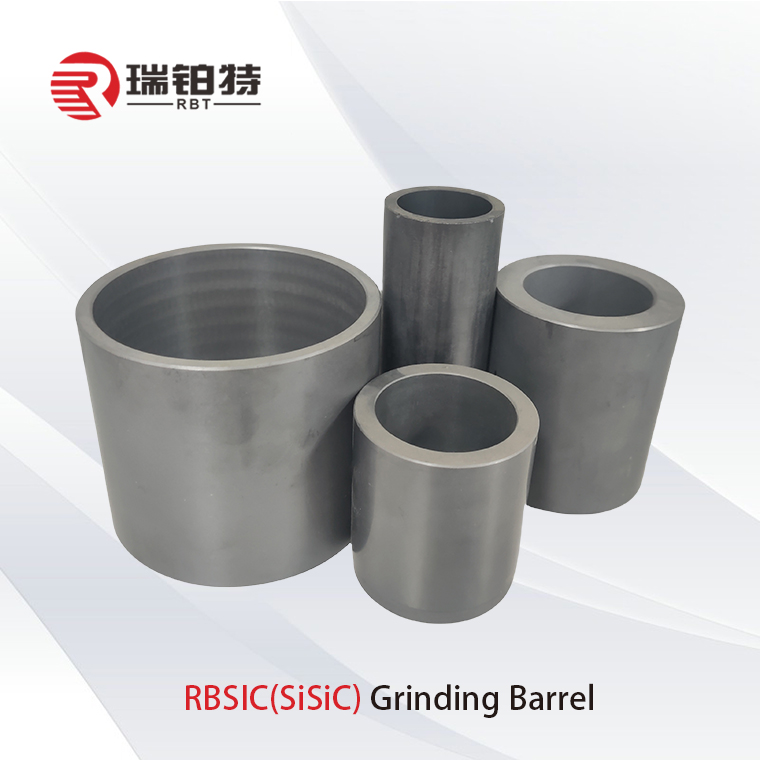

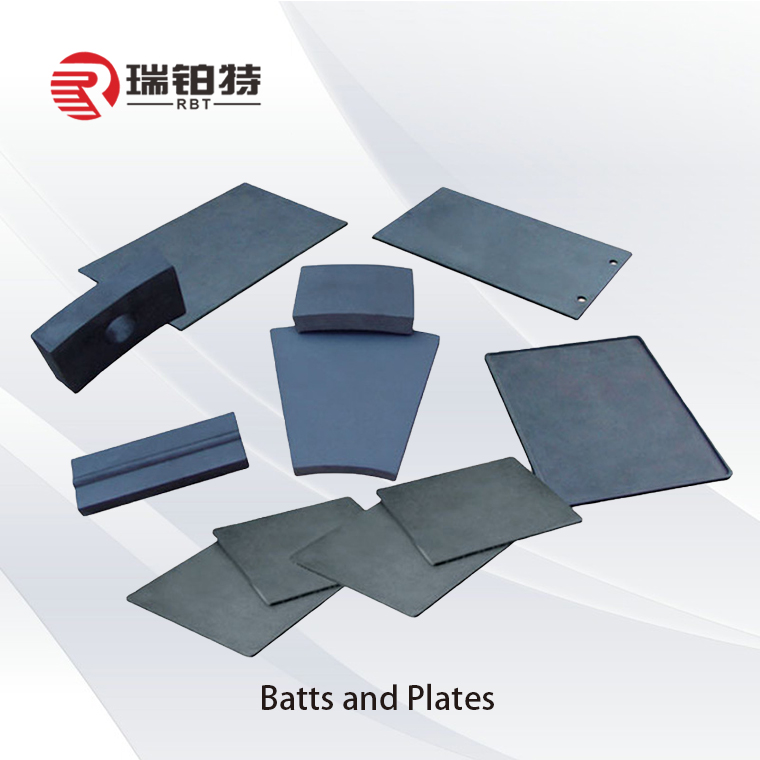

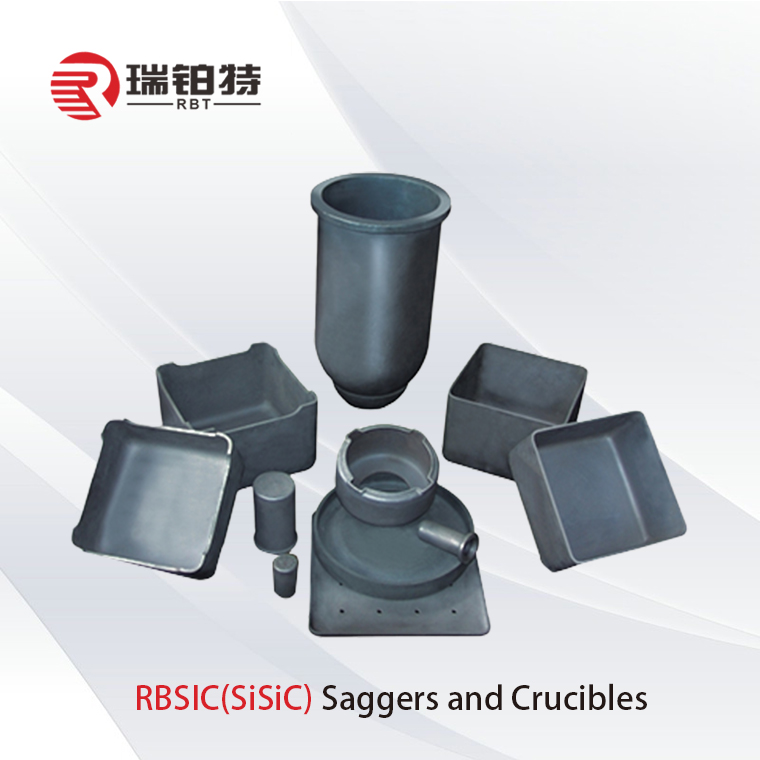

| Njirimara | Ihe nke siliconized carbide siliconized nwere usoro nke isi dị elu na njirimara dị ka ike dị elu, ike siri ike, iyi nguzogide, nnabata okpomọkụ dị elu, nguzogide corrosion, oxidation eguzogide thermal ujo eguzogide, elu thermal conductivity, ala ọnụọgụ nke thermal mgbasa, creep eguzogide n'okpuru. oke okpomọkụ na ihe ndị ọzọ. Enwere ike iji ya mee ọtụtụ ngwaahịa dị ka ogwe, rollers, ọkpọkọ ikuku jụrụ oyi, tubes nchebe di na nwunye na-ekpo ọkụ, tubes na-atụ ihe okpomọkụ, akụkụ akara, na akụkụ pụrụ iche. |

Ndekọ ngwaahịa

| Ihe | Nkeji | Data |

| Oke okpomọkụ nke ngwa | ℃ | ≤1380 |

| Njupụta | g/cm3 | 3.02 |

| Mepee Porosity | % | ≤0.1 |

| Na-ehulata Ike | Mpa | 250 (20 ℃);280 (1200 ℃) |

| Modul nke Elastictiy | Gpa | 330 (20 ℃);300 (1200 ℃) |

| Nrụpụta okpomọkụ | W/mk | 45 (1200 ℃) |

| Ọnụego Mgbasawanye okpomọkụ | K-1*10-6 | 4.5 |

| Ike Moh | | 9.15 |

| Acid Alkaline-ihe akaebe | | Magburu onwe |

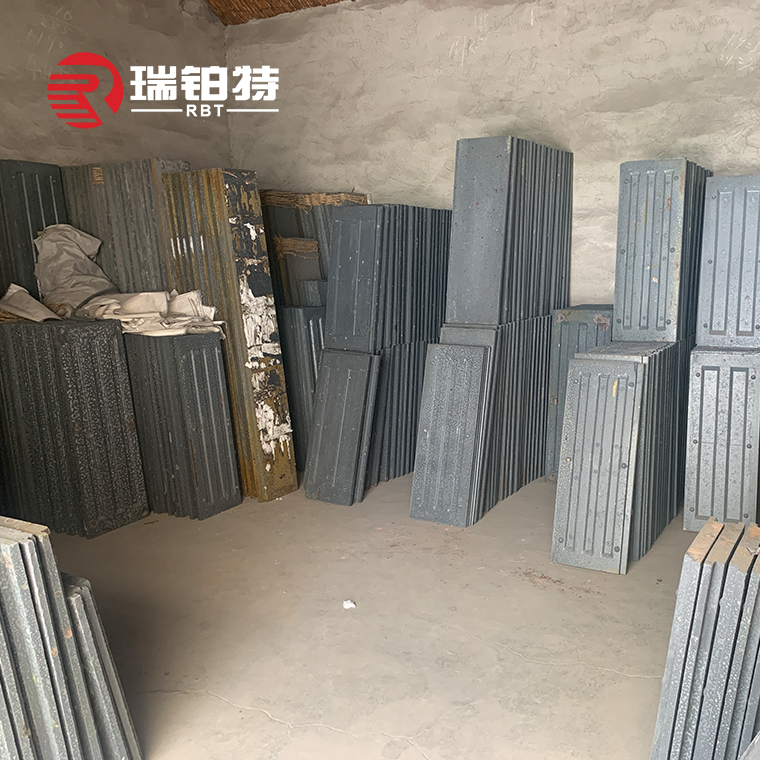

Foto nkọwa

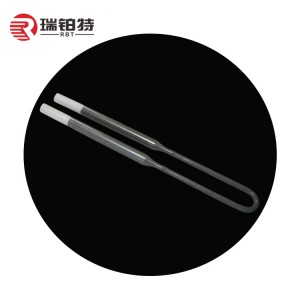

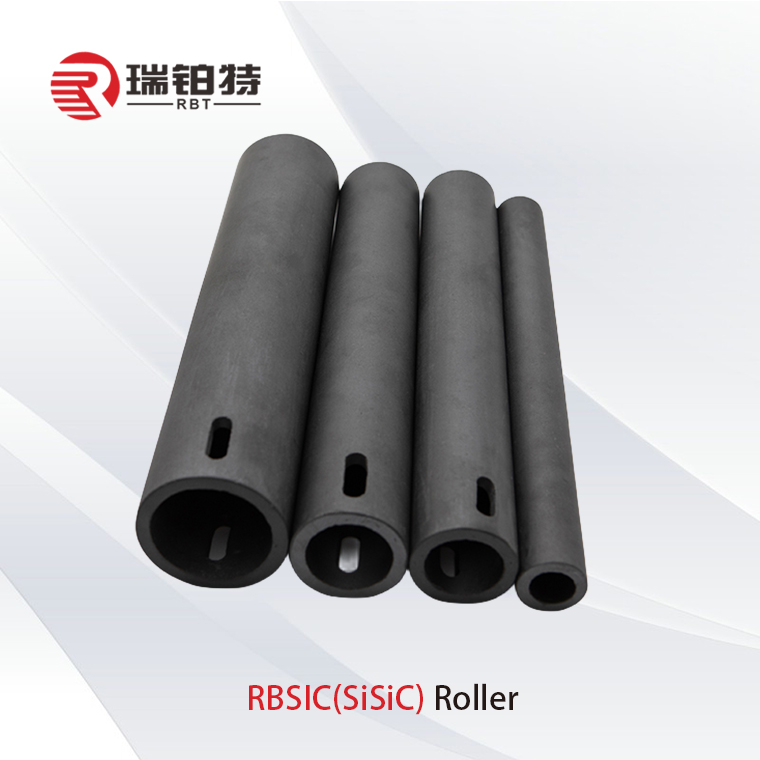

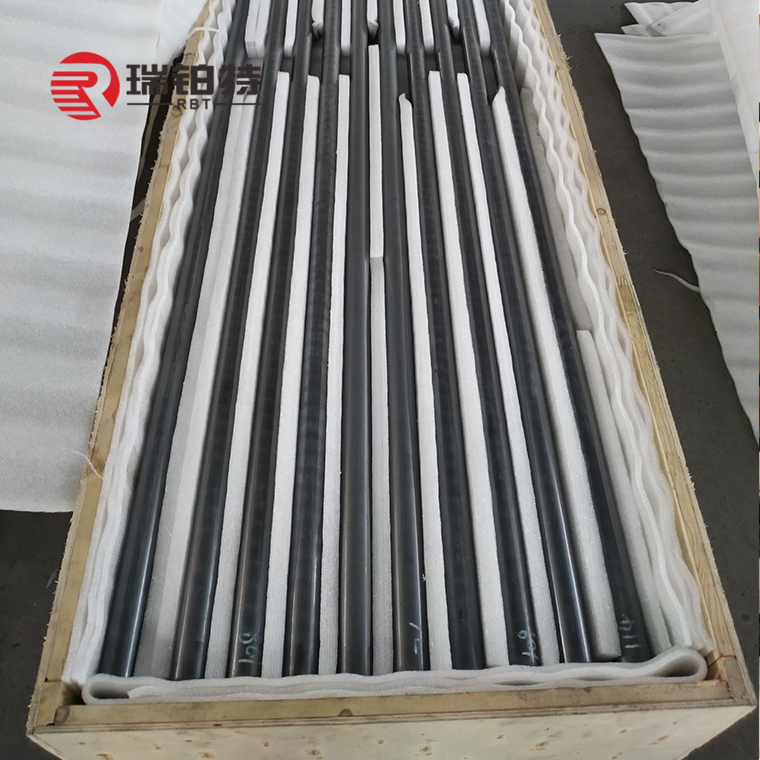

Njirimara:Nguzogide corrosion kemịkalụ kacha mma nke mkpanaka silicon carbide Roll na-eme ka ọ rụọ ọrụ ogologo oge na gburugburu ikuku na-emebi emebi nke igwe eletriki lithium, ma nwee ogologo ndụ.

| Ikike nke RBSic(SiSiC) Rollers | |||

| NhankeNgalaba(mm) | MgbidiỌkpụrụkpụ(mm) | Gbadoro anyaNa-ebu (kg.m/L) | N'otu n'otuKesaraNa-ebu (kg.m/L) |

| 30 | 5 | 43 | 86 |

| 35 | 5 | 63 | 126 |

| 35 | 6 | 70 | 140 |

| 38 | 5 | 77 | 154 |

| 40 | 6 | 97 | 197 |

| 45 | 6 | 130 | 260 |

| 50 | 6 | 167 | 334 |

| 60 | 7 | 283 | 566 |

| 70 | 7 | 405 | 810 |

Ngwa:Ebe a na-egwu mmiri, ebe a na-egwu mmiri, ebe a na-adọba ụgbọala, na ihe ndị ọzọ na-ebu kiln ụlọ ọrụ na ngwaahịa ndị na-ebu kiln.

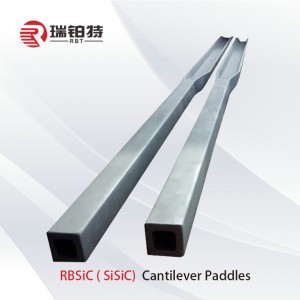

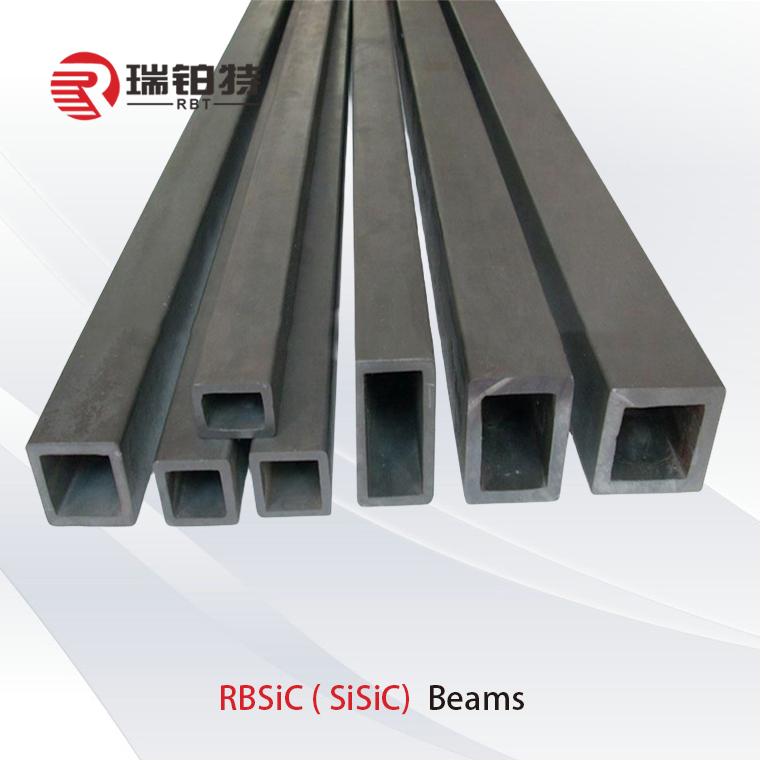

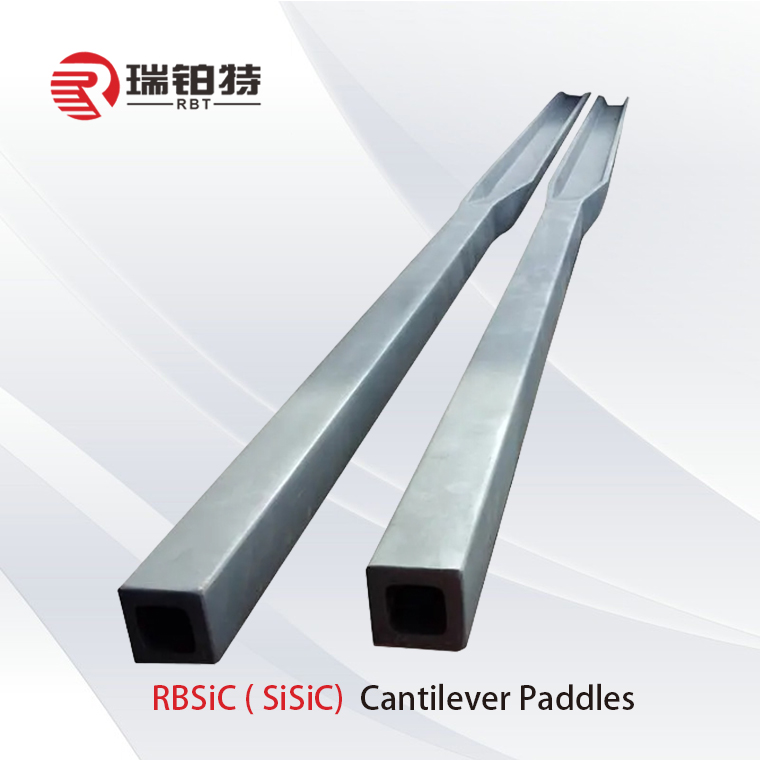

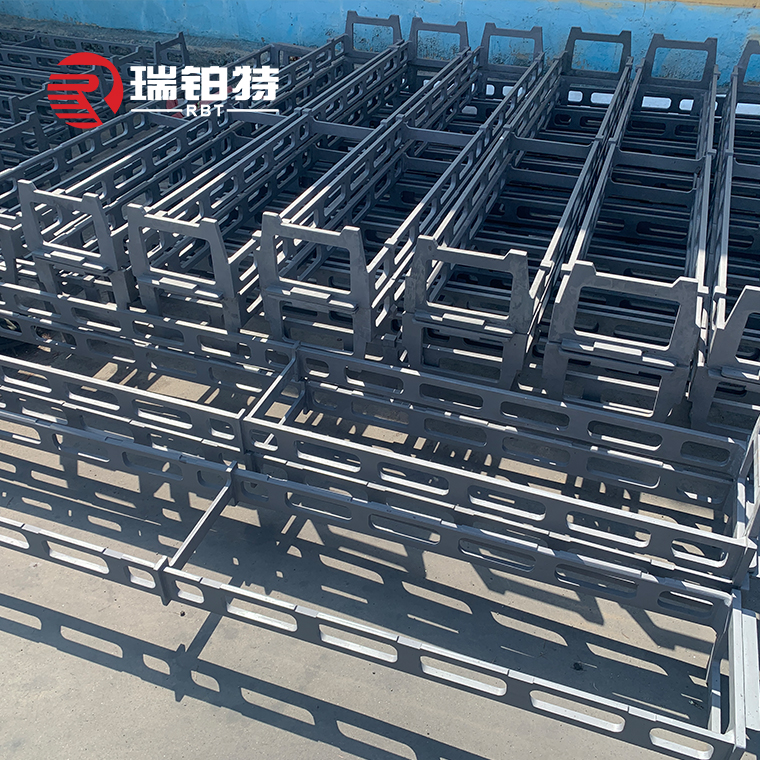

Njirimara:Silicon carbide square beam nwere uru nke nnukwu ikike ibu okpomọkụ dị elu, ezigbo ọkụ eletrik, nguzogide okpomọkụ dị elu na nchekwa ike.Igwe ọkụ eletriki nke lithium maka igwe eletriki igwe eletriki igwe, uzuzu seramiiki, ngwa ihe ocha, seramiki kwa ubochi, igwe eletriki, ihe ntughari, seramiki foam, na ulo oru ndi ozo.

| Ikike nke RBSic(SiSiC) doo | ||||||

| Nha nke ngalaba (mm) | Mgbidi Ọkpụrụkpụ (mm) | Nbudata etinyere (kg.m/L) | Nbudata ekesara n'otu n'otu (kg.m/L) | |||

| Akụkụ B | H Akụkụ | W Akụkụ | H Akụkụ | W Akụkụ | H Akụkụ | |

| 30 | 30 | 5 | 74 | 74 | 147 | 147 |

| 30 | 40 | 5 | 117 | 95 | 235 | 190 |

| 40 | 40 | 6 | 149 | 149 | 298 | 298 |

| 50 | 50 | 6 | 283 | 283 | 567 | 567 |

| 50 | 60 | 6 | 374 | 331 | 748 | 662 |

| 50 | 70 | 6 | 473 | 379 | 946 | 757 |

| 60 | 60 | 7 | 481 | 481 | 962 | 962 |

| 80 | 80 | 7 | 935 | 935 | 1869 | 1869 |

| 100 | 100 | 8 | 1708 | 1708 | 3416 | 3416 |

| 110 | 110 | 10 | 2498 | 2498 | 4997 | 4997 |

Ọkụ Casing

Igwe radieshon

Liners

Na-akwado

Ngwugwu & Ụlọ nkwakọba ihe

Ajụjụ a na-ajụkarị

Achọrọ enyemaka?Jide n'aka na ịga na forums nkwado anyị maka azịza nye ajụjụ gị!

Anyị bụ ezigbo emeputa, ụlọ ọrụ anyị bụ ọkachamara na-emepụta ihe refractory maka ihe karịrị afọ 30.Anyị na-ekwe nkwa ịnye ọnụahịa kacha mma, ọrụ izizi ahịa na mgbe irechara.

Maka usoro mmepụta nke ọ bụla, RBT nwere usoro QC zuru ezu maka ihe mejupụtara kemịkalụ na ihe anụ ahụ.Na anyị ga-anwale ngwongwo ndị ahụ, a ga-ebufekwa akwụkwọ ikike na ngwaahịa.Ọ bụrụ na ị nwere ihe pụrụ iche chọrọ, anyị ga-agbalị ike anyị niile ịnabata ha.

Dabere na ọnụ ọgụgụ, oge nnyefe anyị dị iche.Ma anyị na-ekwe nkwa ibupu ngwa ngwa o kwere omume na mma ekwe nkwa.

N'ezie, anyị na-enye free samples.

Ee, n'ezie, ị na-anabata ileta RBT ụlọ ọrụ na anyị ngwaahịa.

Enweghị oke, anyị nwere ike ịnye ndụmọdụ na ngwọta kachasị mma dịka ọnọdụ gị si dị.

Anyị na-eme ihe refractory ihe karịrị afọ 30, anyị nwere nkwado teknụzụ siri ike na ahụmahụ bara ụba, anyị nwere ike inyere ndị ahịa aka ịmepụta kilns dị iche iche ma nye otu nkwụsị ọrụ.